Custom Metal Panels

From precision custom sheet metal panels for electronics to stunning architectural facades. We fabricate to your exact design specifications with no minimums, tight tolerances, and worldwide delivery.

Why Choose ShincoFab for Custom Metal Panels?

You don’t just need metal sheets, you need certainty. At ShincoFab, we eliminate the risks of poor fitment, late deliveries, and hidden costs. Whether you are sourcing architectural metal panels or precision electronic enclosures, we deliver parts that fit your specs and your schedule.

Built Right the First Time

Your panels have to fit. They also have to last. At ShincoFab, we hold tight tolerances on every bend, hole, and weld. We check parts at each step, not just at the end. Our laserskärning, CNC-styrda kantpressar, and fixture welding make parts repeatable. Corners are clean. Edges are deburred. Flatness and squareness are verified before finish.

Need a certificate or inspection notes? Ask and we’ll include them. We can hold ±0.005 in on critical features when the material and geometry allow. We match grain direction and finish callouts. We protect faces with film so they arrive clean. This is how we make custom metal panels that install fast and look sharp. Fewer surprises on site means less rework and lower cost.

Fast Turn, Any Quantity

Deadlines are real. We move fast. Prototypes ship in as little as 2–3 days. Standard lead times are short and predictable. Order one piece or a few thousand. There is no minimum order at ShincoFab. We scale from quick-turn prototypes to low-volume production without changing your design.

Need an expedite? Say the word. We slot rush jobs without drama. We pack smart and ship worldwide by courier or freight. Your custom metal panels arrive on time, labeled, and ready to use. If you have a critical date, tell us early. We will build the plan with you and hit it. We can stage releases, too. Approve a first article, then we run the rest. That keeps your project moving and your team on schedule.

Designhjälp som sparar pengar

Great results start with a good drawing. Send your model or sketch to ShincoFab. We review designs for manufacturability within 24 hours. We suggest bend radii, reliefs, hems, offsets, and tab sizes that cut cost and improve fit. We call out where slots, notches, or fasteners help assembly. We flag risk areas like tight corners, deep boxes, or warped flats. We also look at material and finish.

Together we choose aluminum, stainless, or steel that suits your job. We talk about powder coat, anodize, chem-film, or passivation. You get clear feedback and a firm quote. You avoid rework in the field. Your custom metal panels go together the first time.

Clear Pricing and Better Communication

Nobody likes surprises. With ShincoFab, you get transparent pricing and steady updates. We break out materials, ytbehandlingar, and hardware so you see where money goes. Quotes are fast and easy to read. Lead times are clear. After you order, we keep you posted at each step. You can reach your project manager by phone, email, or chat. Need to change a hole, a length, or a color? Tell us early and we adjust.

If something risks your date, we say so and offer options. Simple, honest communication helps you plan installs and keep the team aligned. That is how we earn trust on custom metal panels.

Proven Across Many Uses

Your work spans many fields. Ours does too. We build custom metal panels for electronics, kapslingar, racks, and consoles. We make architectural panels for walls, soffits, and facades. We support labs, robotics, audio/visual, medical, and communications projects. Each field has its needs. Maybe you care about EMI/RFI shielding.

Maybe it is heat, weight, or a clean look. We help you pick the right material, thickness, and finish for the job. We can provide material certs on request. We pack panels with protective film to prevent scratches. With ShincoFab, you get parts that fit the use, the site, and the budget. Share your use case, and we’ll show samples and past solutions that match.

Installation-Ready Details

Little details save big time on site. We can pre-assemble where it makes sense. We insert hardware, add gaskets, apply masking, and kit parts by area or level. Holes line up. Edges are safe to handle. We mark panels for location so your team installs fast. We include prints in the box and email them too.

For repeat work, we lock in tools and fixtures so every run matches. Your custom metal panels arrive wrapped, labeled, and ready to bolt up. Fewer trips to the saw. Less drilling in the field. Faster closeout. Tell us how you plan to install, and ShincoFab will tailor packaging and labels to match.

Materials & Sizes Tailored for Your Project

No two projects are identical. Whether you are specifying metal facade panels for a new building or requiring custom sheet metal panels for industrial enclosures, we hold the inventory and supply chain relationships to source the exact metal alloys for panels your BOM (Bill of Materials) requires.

Material Options

We stock a wide variety of metal alloys for panels to balance weight, strength, and korrosionsbeständighet.

Aluminium

The versatile standard for custom aluminum panels. We offer specific commercial and architectural grades including:

- A5052 & A6061: High strength and excellent corrosion resistance, ideal for marine environments and critical electronic enclosures.

- A3003 & A1100: Superior formability for complex metal panel bending and decorative skins.

Steel & Galvalume

For superior structural rigidity and weatherproofing. We utilize Galvalume for maximum longevity in metal siding panels och custom metal roof panels.

Specialty Metals

Stainless steel for hygiene and modern aesthetics, copper for natural patrolling, and weathering steel options.

Panel Sizes & Thickness (Gauge)

From thin-gauge electronic chassis to heavy-duty architectural facade solutions, we fabricate to your exact custom metal panel design specifications.

Thickness / Gauge Flexibility

We handle a full range of metal panel gauge options tailored to structural and aesthetic needs:

- Steel / Galvalume: Från 26 Gauge (0.45mm) for light cladding up to 7 Gauge (4.5mm) plate for structural components.

- Aluminium: Från 0.032″ (0.8mm) skins up to 0.250″ (6.35mm) plate for rugged environments.

Max Dimensions (Seamless Length)

Eliminate unsightly seams on large facades. Leveraging our Jorns JDB Double Bending Machine, we can cut and bend panels up to 21 feet (6.4 meters) in length*.

- Standard Sheets: We stock 4’x10′ and 5’x12′ sheets for rapid turnaround.

- Oversized Capabilities: Perfect for continuous metal enclosure panels, long-span soffits, and wall systems that require clean, uninterrupted lines.

Finishes, Coatings & Surface Treatments

The finish determines the lifespan and look of your product. Our metal panel finishing options ensure durability and visual appeal.

- Pulverlackering: Choose from hundreds of metal panel powder coating colors. This provides a durable, weather-resistant shell perfect for custom metal panels with powdercoat finish.

- Anodizing: Hard-wearing and corrosion-resistant, ideal for custom aluminum facade panels exposed to the elements.

- Texture & Protection: Options include brushing, polishing, and chemical conversion coatings (Chromate) for electrical conductivity in electronics (

EMI/RFI-skärmningready).

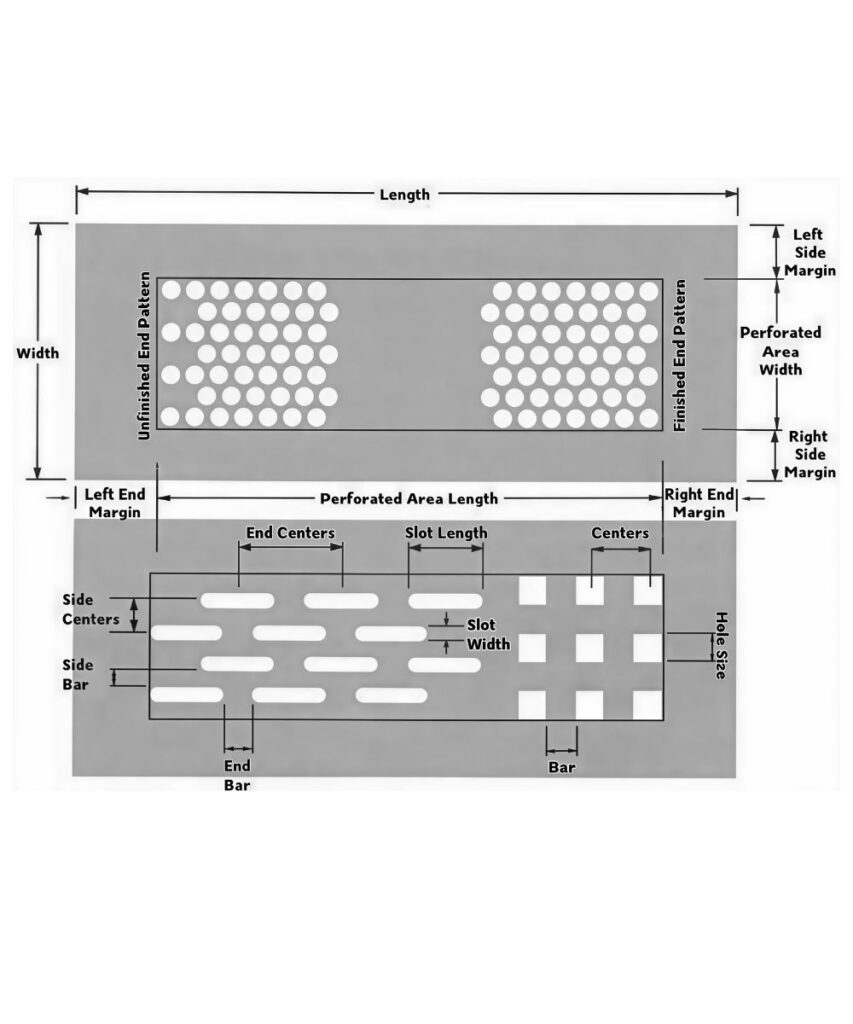

Custom Graphics, Labeling & Perforation

Go beyond the raw metal. Since we handle the entire custom metal panel fabrication process, we offer value-added aesthetic and functional customizations:

- Digital Printing & Graphics: We produce custom metal panels with digital printing and labeling directly on the surface—perfect for instructional text on machinery or branding on custom decorative metal panels.

- Perforation & Laser Marking: From ventilation holes for metal panel heat dissipation to intricate artistic perforation patterns for architectural flair, plus permanent laser marking for part serialization.

Custom Metal Panels That Fit, Last, and Arrive On Time

Stop worrying about tolerances and delays. We combine precision sheet metal fabrication with transparent pricing and rigorous quality checks. Get custom fabricated panels that match your design specifications perfectly—ready to install right out of the box.

Vanliga frågor och svar

Find quick answers below. If you have specific design constraints not covered here, get a free consultation.

Is there a minimum order to fabricate custom metal panels?

Nej, det gör jag inte. Vi är specialiserade på low volume prototype sheet metal fabrication alongside high-volume production. Whether you need a single custom aluminum panel for a mock-up or 5,000 units for a commercial rollout, there is custom metal panels no minimum order requirement at ShincoFab. Keep in mind that unit pricing decreases significantly as volume increases due to setup efficiencies.

What file formats do you accept for quoting?

To get the fastest custom metal panel cost and pricing, we recommend sending 3D CAD models (STEP, IGES, SolidWorks) along with a 2D PDF drawing that calls out critical tolerances, finishes, and threaded inserts. We can also work from DXF/DWG flat patterns. Have a hand sketch? Our team can assist with custom metal panel design specifications to get it production-ready.

What materials and alloys do you stock?

We hold inventory of the most common materials to speed up lead times.

- Aluminium: 5052-H32 (standard for enclosures/facades), 6061-T6 (structural), and 3003 (bend-friendly).

- Stål: Cold-rolled (CRS), Galvanized, and Galvalume för metal siding panels.

- Rostfritt stål: 304 and 316 grades.

- Copper & Brass: Available for decorative architectural applications.

How fast can you deliver? (Lead Times)

Speed is our differentiator.

- Prototyper: Standard lead time is 2–5 days depending on complexity.

- Produktion: Vanligtvis 2-3 veckor.

- Vi erbjuder custom metal panels delivered worldwide. If you have a “line-down” emergency or a tight construction deadline, please flag it as “Expedite” when you request a quote, and we will confirm if we can meet your date.

Can you handle complex shapes like tapered or curved panels?

Yes. Beyond standard rectangles, we fabricate custom tapered metal panels, perforated screens, and complex bent geometries using our Jorns JDB Double Bending Machine and CNC turret punches. From architectural metal facade panels to intricate electronic chassis, if it can be unfolded from sheet metal, we can make it.

What finishes do you offer in-house?

We provide a turnkey solution. You can specify custom metal panels with powdercoat finish (choose any RAL color), anodizing (Clear, Black, Hard), chemical conversion (Alodine/Chem-film for conductivity), or passivated stainless. We also offer custom metal panels with digital printing, silkscreening, and laser marking for logos and labels.

What tolerances can you hold?

För precision sheet metal fabrication, our standard dimensional tolerance is +/- 0.010″ (0.25mm), but we can hold +/- 0.005″ on critical features when specified. For architectural metal panels, we adhere to industry standards for flatness and visual uniformity to ensure seamless alignment on walls and roofs.

How much do custom metal panels cost?

Pricing depends on material gauges, part complexity (number of bends/welds), finish, and quantity.

- Tooling: We use standard turret and brake tooling, so there is rarely a custom tooling fee.

- Setup: One-off parts carry a setup cost; this absorbs into the unit price on larger runs.

To get an accurate price, submit your drawings for a free quote within 24 hours.

Do you offer design assistance (DFM)?

Yes. We don’t just cut; we consult. Our DFM (Design for Manufacturing) review checks your design for feasibility. We often suggest slight changes to bend radii, flange lengths, or metal panel heat dissipation patterns that can reduce costs and improve structural integrity without changing the function of your part.

Contact Us for Custom Metal Panels Services

Don’t fit your project into a standard box. Upload your custom metal panel design specifications (CAD, PDF, or sketches) today. Whether you need a single Prototyp or a high-volume production run, our engineers will review your files for manufacturability and provide transparent pricing. Fast turnaround. No minimums. Secure file handling guaranteed.