Sheet Metal Stamping Services

Discover expert sheet metal stamping services delivering high-quality, precision-engineered metal parts from prototype to mass production. Our advanced capabilities ensure tight tolerances, fast turnaround, and cost-effective solutions tailored to your industry needs.

What is Sheet Metal Stamping Services?

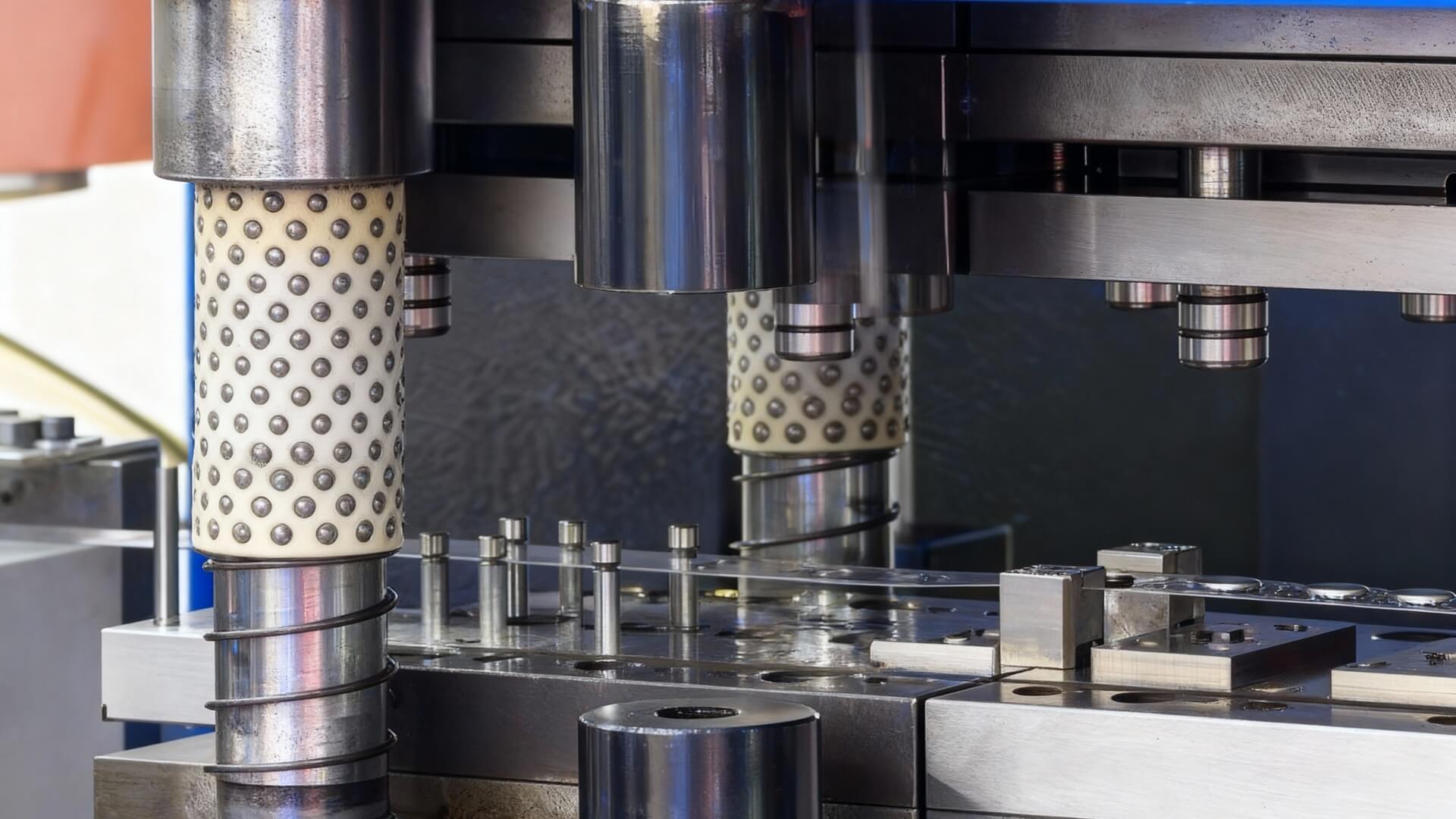

Sheet metal stamping services are all about shaping flat sheets or coils of metal into useful parts. It’s a manufacturing process where we press metal using special tools and dies to cut, bend, punch, or form it into the exact shapes and sizes you need. Whether it’s simple brackets or complex parts for cars, electronics, or appliances, sheet metal stamping helps make parts quickly and with consistent quality.

At ShincoFab, we offer custom sheet metal stamping services that fit your project perfectly. We work with many metals like steel, aluminum, copper, and brass. Our expert team uses modern presses and advanced tooling to deliver parts with tight tolerances and great surface finishes. We handle everything from quick prototypes to big production runs, all designed to keep your costs down and your timelines on track.

What sets ShincoFab apart? We care about making your manufacturing experience easy and reliable. We review every project closely to match the right stamping method to your needs. Plus, our in-house tooling and quality checks ensure your parts come out right, every time. Need finishing touches like powder coating or plating? We have you covered there too.

Ready to get your metal parts stamped with precision and speed? Contact us at ShincoFab today. Let’s bring your designs to life smoothly and affordably!

Our Sheet Metal Stamping Capabilities

Looking for sheet metal stamping services that cover it all? At Shinco, we build precise parts fast, from prototype to high-volume production. Send us your CAD and get a fast quote today. If you don’t see what you need below, just ask—we’re here to help.

01.

Types of Stamping We Offer

Progressive Die Stamping

Get the best cost per part at scale. At ShincoFab, we run high-speed progressive lines for complex parts with multiple features in one pass. Great for brackets, clips, terminals, and shields.

Deep Draw Stamping

Need cups, cans, housings, or enclosures with depth? We form deep shapes with smooth walls and tight roundness. ShincoFab keeps draw ratios and radii dialed in to avoid splits and wrinkles.

Fourslide/Multislide Stamping

For small, intricate parts with bends from multiple directions. Ideal for clips, springs, and connectors. Fast set-ups and great repeatability at ShincoFab.

Transfer Die Stamping

Perfect for larger or 3D parts that require staged forming. We move parts through each station for complex shapes without marking the surface.

Blanking and Piercing

Clean, consistent edges for flat parts and pre-forms. We hold tight hole-to-edge control and minimize burrs with tuned dies at ShincoFab.

Embossing and Coining

Add logos, textures, and raised features. We coin sharp details for conductivity, fit, and looks.

Bending and Forming

Accurate bends and hems at the right angles every time. We manage springback with DFM and try-out runs so your parts fit on the first go.

02.

Material Options and Thickness Ranges

We work with common and specialty metals. If your grade isn’t listed, ask—we can source it.

Stainless Steel (304, 316, 301, 430)

- Typical thickness: 0.2–3.0 mm

- Uses: brackets, shields, enclosures, food/med parts

Carbon Steel / Mild Steel (CRS, HRPO)

- Typical thickness: 0.3–6.0 mm

- Uses: structural parts, frames, hardware

HSLA and Spring Steel (AISI 1050–1095)

- Typical thickness: 0.3–2.5 mm

- Uses: clips, springs, energy-absorbing parts

Aluminum (1100, 3003, 5052, 6061)

- Typical thickness: 0.3–4.0 mm

- Uses: light-weight covers, housings, heat shields

Copper and Brass (C110, C260, C268)

- Typical thickness: 0.2–2.5 mm

- Uses: terminals, EMI/RFI shields, electrical parts

Galvanized and Galvannealed Steel

- Typical thickness: 0.5–3.0 mm

- Uses: corrosion-resistant brackets and panels

We can add finishes too: plating, anodizing, passivation, powder coat, e-coat, and more. Send your spec and we’ll match it. Get a quote now.

03.

Volume Capabilities: From One-Offs to Millions

- Prototype (1–50 parts): Fast turn using soft tools or laser + form. Great for testing and fit checks. Prototypes in days.

- Low Volume (50–5,000 parts): Stage tooling keeps costs low and lead times short. ShincoFab tunes the process to your budget.

- Medium Volume (5,000–100,000 parts): Progressive or transfer tooling balances piece price and uptime for steady demand.

- High Volume (100,000+ parts): High-speed progressive lines with auto feeding and in-die sensors for quality and scale.

04.

Typical Tolerance Levels We Achieve

- Standard features: ±0.10 mm

- Tight features on small parts: down to ±0.05 mm (with DFM)

- Hole-to-hole and hole-to-edge: ±0.10–0.15 mm

- Burr after deburr: ≤0.05 mm

- Flatness: controlled per part size and material; we’ll set realistic, proven limits in DFM

We support FAI, PPAP, CPK, and full inspection reports. Our team at ShincoFab reviews your drawing and offers simple edits to hit your tolerances at the best cost. Send your print for a quick review.

05.

Quick Capability Snapshot

- Progressive die: Best for high volume, complex parts — Typical tolerance: ±0.05–0.10 mm

- Deep draw: Best for cups, cans, housings — Wall control and roundness held tight

- Fourslide: Best for small, intricate bends — Fast set-ups, great repeatability

- Transfer die: Best for larger 3D forms — Multi-stage forming without surface damage

- Blanking/piercing: Best for flat profiles and holes — Clean edges, low burr

- Embossing/coining: Best for logos, textures, fine details — Crisp, repeatable features

- Bending/forming: Best for angles, hems, flanges — Springback managed with DFM

Why Choose Our Sheet Metal Stamping Services

Why we’re the right partner for your sheet metal stamping services. At ShincoFab, we make it easy to get precise parts, fast. Read on to see how we deliver quality, speed, and value on every job. Have a project in mind? Contact us now and let’s talk through your drawings and goals.

01.

Prototype-to-Production, Seamless

We help you start smart and scale smoothly. Kick off with fast prototypes, soft tooling, or laser-cut blanks to prove form and fit. When you’re ready, we move to progressive die stamping, transfer stamping, or deep draw for high-volume runs. Same team. Same specs. No drama. This flow keeps costs down and lead times short while protecting your deadlines.

You’ll get DFM feedback early so bends, holes, and grain direction work in the press. That means fewer tool changes and fewer surprises. With ShincoFab, you can bridge from short-run stamping to millions of parts without changing your design intent. Send your CAD for a free DFM review and a quick quote.

02.

Tooling Done Right, In‑House

Great stampings start with great tools. Our in-house tool and die team designs and builds progressive, transfer, and single-hit dies for your part. We plan strip layouts for high material yield and stable forming. We model critical bends and draw ratios to cut risk before the first hit. Then we run tryouts and sample parts so you can approve with confidence.

We also maintain what we build. ShincoFab tracks preventive maintenance, regrinds inserts on schedule, and keeps spare details ready. That keeps your line running and your dimensions steady over long runs. Need quick corrections or EO changes? Our in-house crew turns them fast. Talk to our tooling team to align on the best approach.

03.

Quality You Can Trust

You expect tight tolerances and clean edges. We build quality into the process. First article inspections, control plans, and SPC checks keep parts on-size. We validate critical features like hole-to-bend, flatness, and burr height. Typical outcomes hit tight tolerances and stable repeatability across lots.

We work to ISO-driven systems and can support APQP and PPAP submissions when your program needs them. Material certifications, traceability, and gauge R&R are part of our routine. At ShincoFab, your parts arrive with the data you need and the finish you expect. Need PPAP Level 3, cleanliness specs, or special packaging? Tell us early and we’ll build it into the plan. Request sample parts and a full inspection report.

04.

Speed, Cost, and Transparency

We move fast without cutting corners. Quotes turn around quickly, and our lead times are honest. We show tooling costs up front and explain cost-down levers: coil width, nesting, in-die operations, and fewer secondary steps. You see where the money goes, and how to save it.

During production, you get clear status updates, photos, and dates you can trust. If a risk shows up, we tell you early and fix it fast. ShincoFab believes in “no surprises” service. That’s how we keep your build on schedule and on budget. Share your target price and volume—let’s build a cost plan that works.

05.

Capability That Fits Your Part

Your part drives the process. We run progressive die stamping for high-speed, high-repeatability parts. We use deep draw stamping for cups, housings, and cans. We use transfer and fourslide when forms get tricky. We also handle blanking, piercing, bending, forming, embossing, and coining.

Materials include low-carbon steel, HSLA, stainless 304/316, aluminum 5052/6061, copper C110, brass, and more. We support common thicknesses from thin gauge to heavy sheet. Finishes and secondary ops—zinc or nickel plating, anodizing, powder coat, heat treat, tapping, PEM inserts, spot/MIG/TIG welding, and assembly, make your parts assembly-ready. Ask ShincoFab for a capability check and sample timelines.

06.

Reliable Delivery and Clear Communication

You get a dedicated project owner who answers fast. We share build gates, tryout dates, and shipment plans, so you always know what’s next. Need PPAP samples, run-at-rate, or special pack-outs? We set that up early and ship on time.

For ongoing programs, we can hold buffer stock, set Kanban, or plan releases to match your line. ShincoFab can also help with export-ready packaging and logistics. Our goal is simple: your parts arrive on spec, on time, and ready to use. Message us to set your delivery plan now.

07.

Designed for Your Industry

Automotive needs PPAP and tight repeatability. Electronics need clean edges and precise piercings. Medical and energy need traceability and clean finishes. We get it. We tune the process to your standards, drawings, and compliance needs.

ShincoFab supports brackets, clips, covers, housings, shields, bus bars, and structural parts. We build for performance in real-world conditions—vibration, heat, corrosion, and load. Tell us your industry and environment. We’ll match materials, finishes, and controls to fit. Let’s align your spec and the right stamping route today.

08.

Sustainability and Scrap Reduction

Good engineering is green engineering. We boost material utilization with smart strip layouts and coil selection. We reduce secondary steps by adding in-die processes where it makes sense. We recycle scrap, manage energy use, and suggest finishes with lower impact when possible.

At ShincoFab, better yield and fewer reworks mean lower cost and less waste. That’s good for your budget and the planet. Want a yield study on your part? Send your file and we’ll show you where we can save.

Precision You Can Trust: Sheet Metal Stamping Services That Deliver

Ready to turn your designs into high-quality metal parts? Our sheet metal stamping services offer fast, accurate, and cost-effective solutions tailored to your needs. Whether you need prototypes or large runs, we’re here to help you get it right—on time and on budget.

Frequently Asked Questions

Here are answers to some of the most common questions about our sheet metal stamping services. We want to make sure you feel confident and informed when working with us.

What is sheet metal stamping?

Sheet metal stamping is a process where flat sheets of metal are shaped into parts using a die and press. It’s great for making everything from simple brackets to complex parts, fast and at scale.

What materials can you stamp?

How precise are your stamped parts?

Our sheet metal stamping services achieve tight tolerances, often within a few thousandths of an inch. That means your parts will fit and work exactly as designed, which is critical for quality assemblies.

What are the typical production volumes you support?

We handle it all—from small prototype runs with just a few pieces to large mass production runs of millions. Whatever your volume needs, we can find the right stamping solution for you.

How long does it take to get parts?

Lead times vary depending on the project complexity and volume. But we always aim to be fast and transparent. We’ll give you a clear timeline upfront and keep you updated throughout the process.

Can you help me optimize my design for stamping?

Absolutely! Our team offers design for manufacturing (DFM) advice to make sure your part is easy to produce, cost-effective, and high quality. Feel free to send us your drawings for feedback.

Do I need to provide a finished design to get started?

No worries if your design isn’t final. We can work with sketches, CAD files, or even samples. The earlier we get involved, the more value we can add by helping improve your design.

What finishing options are available?

We offer a range of finishing services like powder coating, anodizing, plating, polishing, and deburring. These help improve part appearance, durability, and corrosion resistance.

Is there a minimum order quantity?

We understand that every project is different. We don’t have strict minimums, so even if you just need a few pieces for prototyping or a short run, we’re happy to help.

How do you ensure quality in sheet metal stamping?

We perform detailed inspections at every step—from incoming materials to final parts. Our quality team uses gauges and testing methods to make sure your parts meet all specifications before shipment.

Get In Touch for Your Sheet Metal Stamping Services Needs

Have questions or ready to start your next project? We’re here to help with all your sheet metal stamping services. Whether you need a quick quote, design advice, or want to discuss volume options, just reach out. Let’s work together to deliver quality, precise stamped metal parts that fit your goals. Contact us today and get the support you deserve!