Sheet Metal Punching Services

Delivering fast, accurate, and customizable sheet metal punching solutions tailored to your material and design needs. Trust our expert team and advanced technology to produce high-quality punched parts with tight tolerances and quick turnaround.

What is Sheet Metal Punching?

Sheet metal punching is a process where we use special tools to make holes, shapes, or forms in metal sheets quickly and accurately. Think of it like a giant hole punch for metal. We press the metal between a punch and a die, cutting or shaping it exactly how you need.

At ShincoFab, we offer top-quality sheet metal punching services. Whether you need simple holes or complex patterns, we have the right tools and skills to get the job done right. Our machines handle different metals and thicknesses, so you can trust us with any project size—from one-off prototypes to large production runs.

What makes us stand out? We combine speed with precision, making sure your parts meet tight tolerances every time. Plus, our friendly team is here to help you through the whole process. Need advice on your design or quick turnaround times? Just ask!

Ready to get started? Contact ShincoFab today, and let’s punch your sheet metal parts with quality and care.

Comprehensive Punching Capabilities

Need reliable sheet metal punching? At ShincoFab, we make clean, precise parts fast. From prototypes to production, our team and tools are ready to help. Send your CAD file to get a quick quote or chat with an engineer today.

01.

Materials We Work With

We punch a wide mix of metals so you can keep your BOM simple with one supplier. If you don’t see your material here, ask us—Shinco can source it.

- Carbon steel (CRS, HRPO, galvanized, galvannealed): 0.028″–0.187″ (0.7–4.8 mm)

- Stainless steel (304/316): 0.024″–0.150″ (0.6–3.8 mm)

- Aluminum (5052/6061): 0.032″–0.250″ (0.8–6.35 mm)

- Copper and brass: 0.024″–0.125″ (0.6–3.2 mm)

- Pre‑coated and specialty sheets (aluzinc, zinc-plated, pre‑painted, film‑protected)

Not sure what’s best? We’ll help you pick the right alloy and thickness. Contact Shinco for a free DFM check.

02.

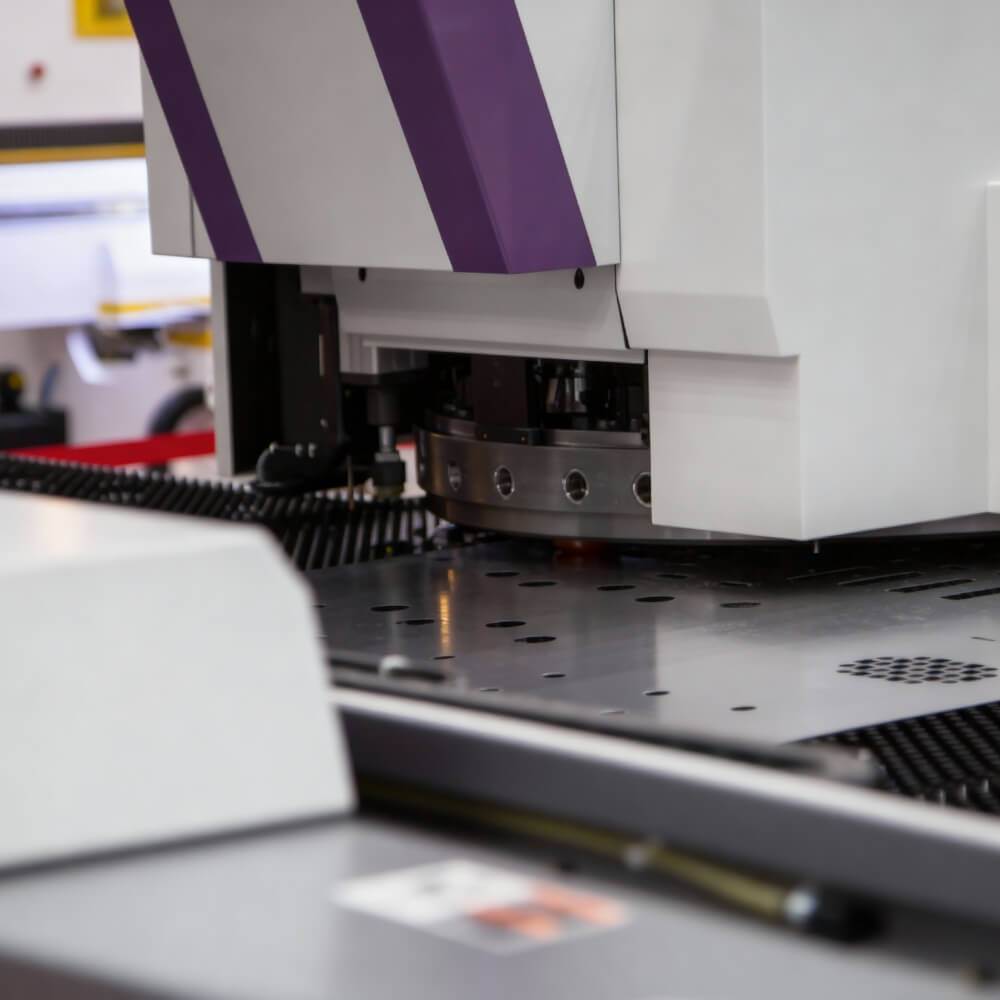

Advanced Equipment & Tooling

We combine speed, accuracy, and flexibility so your parts ship on time and fit right the first time.

- CNC turret punch presses with auto‑index and live tooling

- Punch + fiber laser combo for complex contours and tight corners

- Press force range: 25–50 tons for clean shearing and forming

- Max sheet size: up to 60″ x 120″ (1524 x 3048 mm)

- Brush and ball tables for scratch‑free handling of coated materials

- Offline CAD/CAM programming and simulation for fast setups

- Nibbling for large radii and smooth arcs

- Tapping and thread forming in-machine (common: M3–M8, ask for others)

Tell us what you need, and we’ll match it to the right ShincoFab machine and tool set.

03.

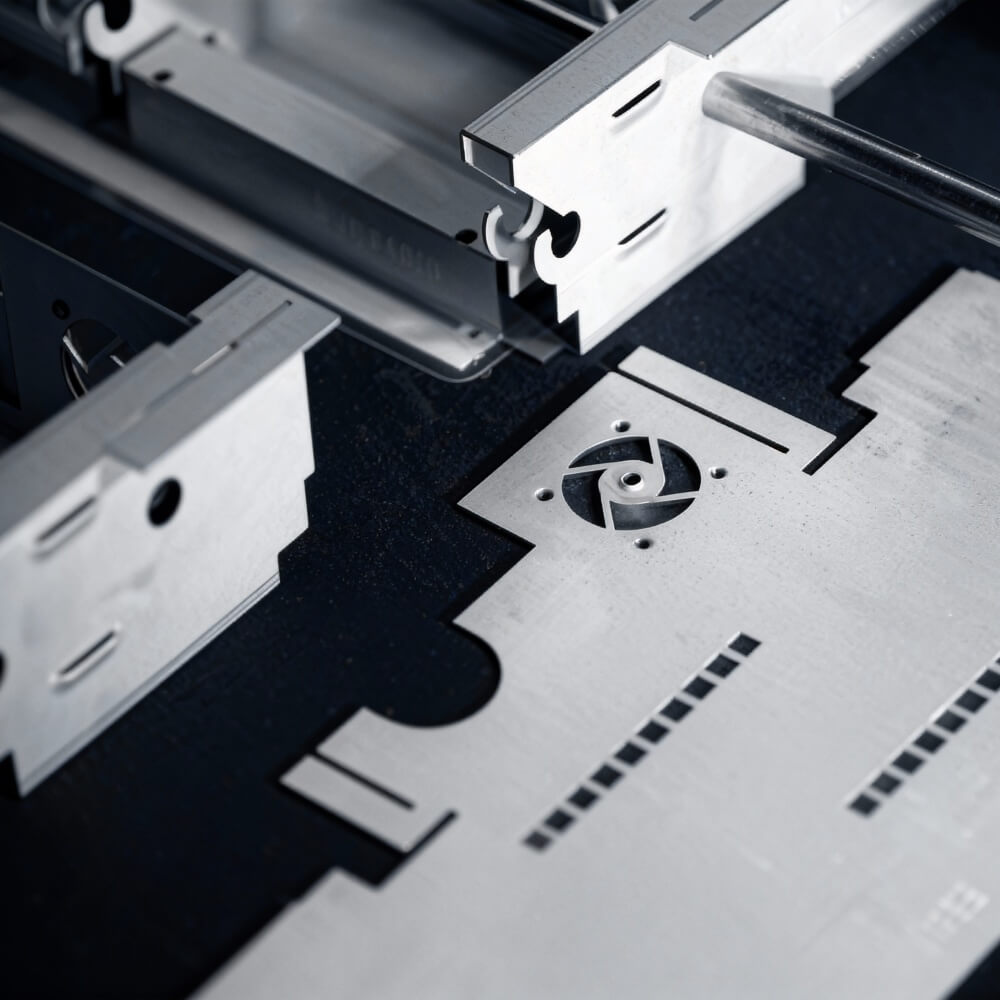

Feature Library (What We Can Punch and Form)

We stock a deep library of standard and special tools. Custom profiles are available on request.

- Louvers – slotted vents for airflow and thermal management

- Ribs – stiffening features to reduce weight and oil‑canning

- Emboss and dimples – clearance, aesthetics, or part IDs

- Extrusions – pull‑through bosses for stronger threads and standoffs

- Countersinks and counterbores – hardware-ready holes

- Half‑shear – location marks and snap‑fit tabs

- Knockouts – electrical cutouts and access panels

- Lance tabs and bridge lances – clips, hooks, and cable features

- Perforation clusters – fast, dense hole patterns

- Marking/engraving – part numbers and logos

- Threading – tapping and thread forming to spec

Need a unique shape? ShincoFab can order or grind custom punch tooling for your project.

04.

Part Size & Volumes

Whether you need one part or one million, we’ve got you.

- Sheet size: up to 60″ x 120″ (1524 x 3048 mm)

- Smallest practical hole: typically ≥ 1.2× material thickness

- Spacing and edge distance: we’ll optimize to your thickness and tool station

- Volumes: prototypes, pilot runs, and full production

- Lead times: as fast as 3–5 days on simple work; standard 7–10 days

Send your drawing to ShincoFab for a same‑day review and timeline.

05.

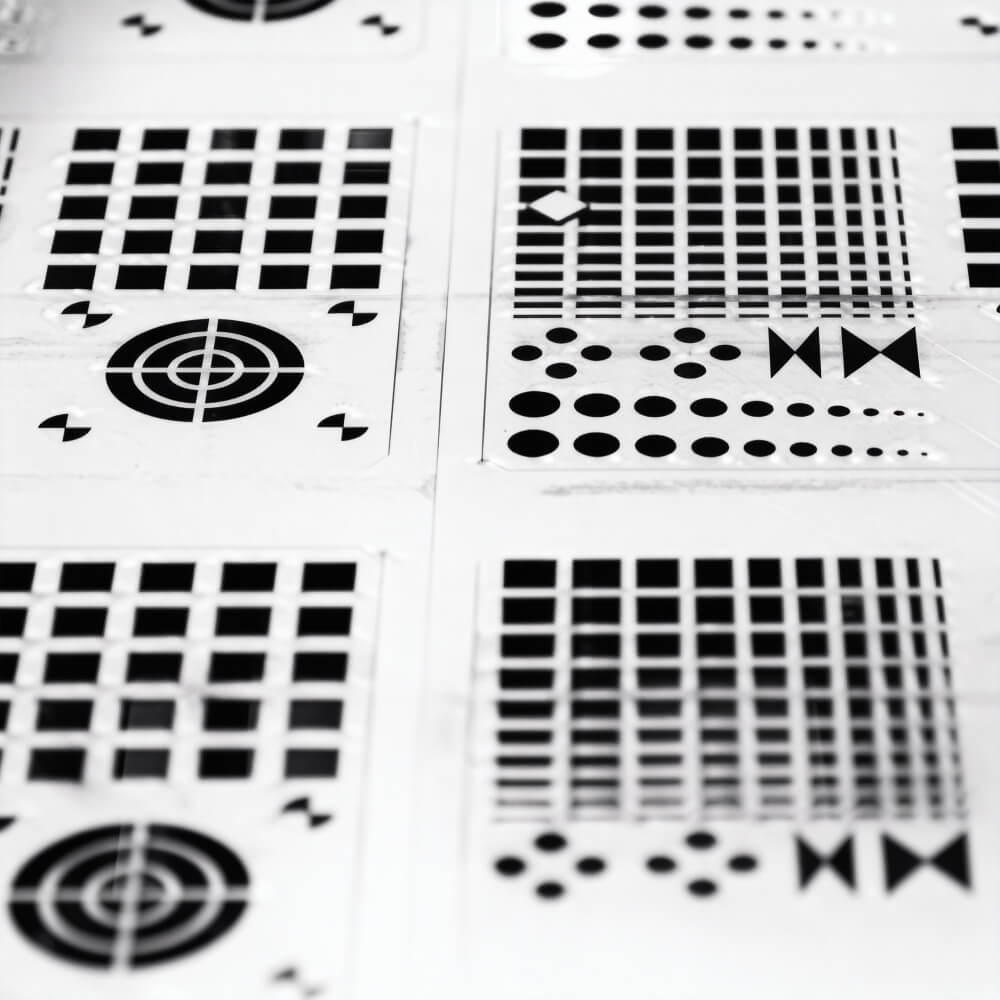

Tolerances & Quality

We build for precision and repeatability, and we’re happy to hold tighter where your design needs it.

- Typical punched features: ±0.005″ (±0.127 mm)

- Hole‑to‑hole and pattern true position: to ±0.003″ on request

- Profile/perimeter after punch or combo laser: ±0.005″–±0.010″

- Formed features (louvers, ribs, emboss): ±0.010″–±0.015″

- Surface care: brush tables and film protection to reduce scratching

Not sure what tolerance to call out? Ask ShincoFab for a quick DFM consultation—we’ll help you balance cost and fit.

Why Choose Our Sheet Metal Punching Services

This is where we show why we’re the right fit for your sheet metal punching work. At ShincoFab, we blend precision, speed, and friendly support so your parts arrive right and on time. If you’re comparing options, read on. Then contact us to review your CAD and get a fast quote.

01.

Precision You Can Measure

You want parts that fit the first time. So do we. Our CNC turret punching and combo punch–laser setups hold tight, repeatable tolerances on holes, slots, louvers, ribs, and embossed features. Typical punch features land within ±0.005 in, with tighter callouts possible by feature and alloy.

We use auto-index tooling, cluster tools for perforation, and in-process checks to keep every hit consistent. Need countersinks, half-shears, knockouts, or thread forms? We’ve got tools for that. At ShincoFab, we also run sample and FAI when needed, and we document critical dims so you have proof in hand. The result is clean edges, accurate centers, and reliable fit-up across builds. Send us your print and we’ll confirm the best path to hit your spec.

02.

Fast Turnarounds Without the Stress

Deadlines are real. We plan for them. Our offline programming, robotic tool changes, and stocked tool library cut setup time so we can start faster. For many sheet metal punching jobs, we ship in days, not weeks. Need to move even quicker? Ask about rush slots and weekend runs.

When a profile is too unique for a standard punch, we pair punching with laser cutting to avoid long tooling lead times and still hit schedule. Brush tables protect surfaces while we keep feed rates high. You’ll get clear dates, simple tracking, and steady updates from the ShincoFab team. If your schedule changes, we flex with it. Share your target dock date when you contact us, and we’ll build a plan around it.

03.

Helpful DFM, From Quote to First Part

Good parts start with good guidance. We offer a quick, free design review to help you tune features for punching. We’ll flag minimum hole size (aim 1.2× thickness), spacing (about 1.5× thickness from edges and bends), and max formed heights (around 4× thickness) so features form cleanly. We’ll also suggest where cluster tools can slash cycle time, or where a short laser op beats custom tooling.

Want louvers for airflow, embosses for standoffs, or ribs for stiffness? We’ll show what works best by alloy and gauge. At ShincoFab, you get real, practical advice you can use right away. Send STEP, DXF, DWG, SLDPRT, or PDF and we’ll return clear notes, pricing options, and lead times. Have questions live? Book a quick call when you contact us.

04.

One Shop for Materials, Finishes, and Assembly

Simplify your supply chain with one PO. We punch mild steel, stainless steel, aluminum, galvanized, brass, and copper across common gauges. Then we finish and assemble in-house: hardware insertion (PEM), tapping/thread forming, welding, riveting, powder coat, anodize, alodine, plating, wet paint, masking, part marking, and careful packing.

Need labeled kits or subassemblies? We do that, too. ShincoFab manages each step so your parts show up ready to use or bolt into your build. We protect coated and brushed surfaces with films and brush-table handling to avoid scratches. Tell us the look, the environment, and the budget when you contact us, and we’ll guide you to the right finish and assembly flow.

05.

Scales From Prototype to Production

Whether it’s one-off prototypes, bridge builds, or steady production, we size our process to your needs. For early runs, we rely on CNC sheet metal punching with standard tools to move fast and learn. As demand grows, we add cluster tools, nibbling strategies, or progressive stations to drive down cost per part.

When geometry calls for it, we combine laser cutting and punching in one program to keep accuracy high and setups short. With ShincoFab, you can ramp from 1 to 1,000+ without changing vendors, drawings, or expectations. We’ll lock in repeatability, set reorder terms, and offer stocking or Kanban when helpful. Share your forecast when you contact us and we’ll plan capacity around it.

06.

Quality, Compliance, and Care for Surfaces

Quality isn’t a checkbox—it’s the whole job. We build to ISO 9001 practices with lot traceability, COC on request, and clear inspection plans for critical features. Our SPC checks catch drift before it becomes rework. We punch on brush tables and use protective films on sensitive sheets to prevent marring.

For stainless and precoated materials, we pick tools and dies that minimize burr and marking. Need PPAP, FAI, or special test reports? ShincoFab will line them up. If your parts have tight cosmetic needs, tell us early so we can tune the program and packing. Reach out now, and we’ll set the right quality plan from the start.

07.

Clear Communication, Start to Finish

You shouldn’t have to chase updates. We give you one point of contact, straight answers, and fast responses. Quotes are simple and transparent, with options to hit budget or speed. We accept common CAD formats and can help clean files if needed. Need an NDA?

We’ll sign it. Have a last-minute change? We’ll talk through the impact on tooling, tolerance, and lead time so you can choose with confidence. With ShincoFab, you always know what’s next. Contact us today, send your files, and let’s build a plan that works for you.

Discover Reliable Sheet Metal Punching Made Easy

Get your sheet metal parts punched right the first time. We deliver fast, precise, and customizable punching services that fit your exact needs. Whether it’s prototypes or production runs, we’ve got you covered.

Frequently Asked Questions

Welcome to our FAQ section, where we answer your top questions about sheet metal punching. Whether you’re new to the process or looking for quick info, we’re here to help you understand how sheet metal punching works and how it can fit your project needs. If you don’t find what you’re looking for, feel free to reach out anytime!

What is sheet metal punching?

What types of metals can be punched?

How thick can sheet metal be for punching?

Can you punch custom hole sizes and shapes?

What tolerances can I expect with sheet metal punching?

What is the typical lead time for punched parts?

Can punched sheet metal parts be finished or coated?

How do I send a design for punching?

Is sheet metal punching suitable for both prototypes and production runs?

Yes, punching is ideal for quick prototypes and also scales well for large production volumes. Our equipment handles small runs and high-volume orders with consistent quality.

What should I keep in mind when designing parts for punching?

Space holes and features at least 1 to 1.5 times the material thickness apart to prevent distortion. Also, avoid overly complex shapes in small sizes and follow design-for-manufacturing guidelines. We’re happy to review your designs to help improve manufacturability.

Contact Us About Sheet Metal Punching Services

Have questions or ready to start your next project? We’re here to help with all your sheet metal punching needs. Whether you want a quick quote, expert advice, or have a custom design to discuss, just reach out. Our friendly team is eager to guide you every step of the way and make sure your parts come out just right. Let’s connect today and bring your sheet metal punching project to life!