Metal Welding Service

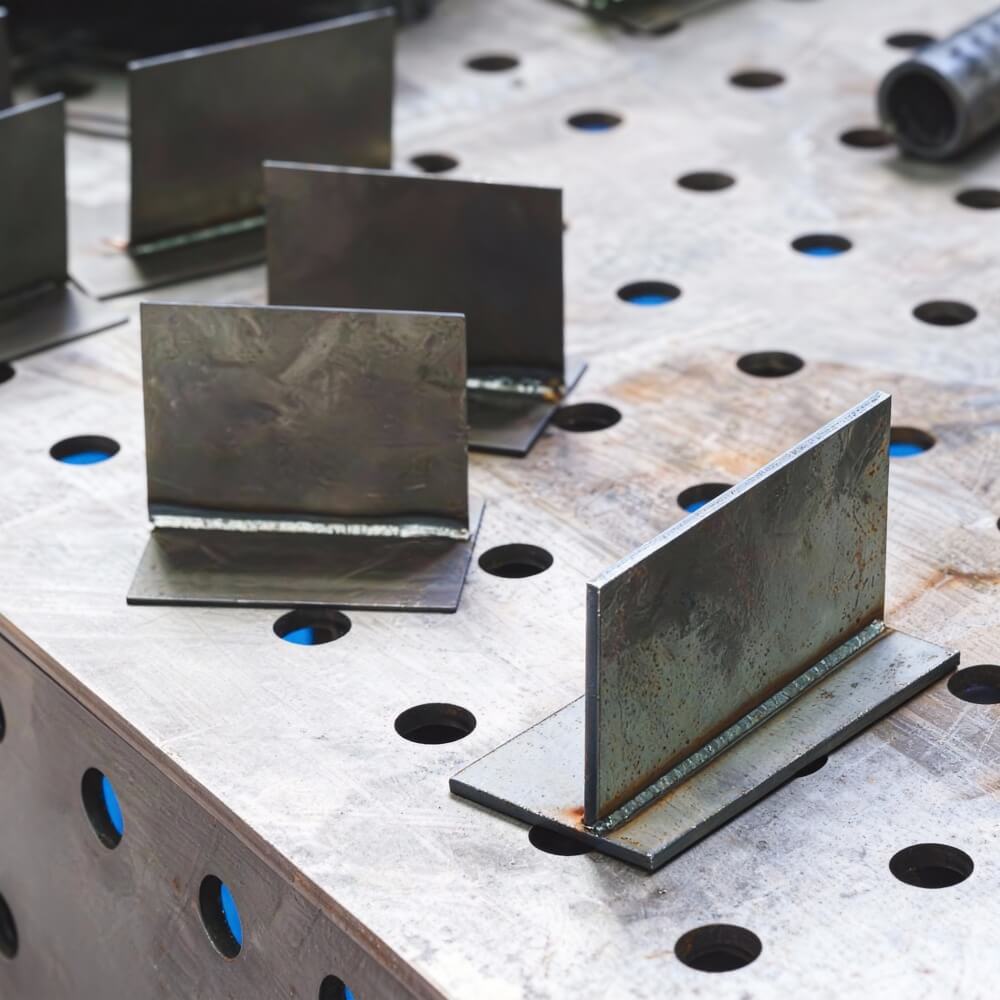

ShincoFab's metal welding service delivers expert fabrication and repair solutions using advanced welding techniques. Trusted by industries for strong, reliable welds that meet safety standards and project deadlines efficiently. Request your quote today for quality welding results.

What is Metal Welding Service?

Metal welding service means joining different pieces of metal together by heating them until they melt and fuse. It’s a way to create strong, lasting bonds that hold parts and structures firmly in place. Whether you are building new equipment, repairing broken metal parts, or making custom metal assemblies, welding is often the best choice for solid, reliable results.

At ShincoFab, we offer metal welding services that help bring your projects to life. We work with many types of metals like steel, stainless steel, aluminum, and more. Our skilled welders use tried-and-true welding methods such as MIG, TIG, and spot welding to handle jobs big and small. We pay attention to every detail so your welded parts meet all quality and safety standards.

What makes us different? We focus on clear communication, quick turnaround times, and personalized support. You’ll get friendly help from start to finish—whether you need advice on which welding method suits your project or want a fast, accurate quote. With ShincoFab, you get reliable metal welding service without the hassle.

Ready to get your metal parts welded right? Contact ShincoFab today, and let’s talk about how we can help with your welding needs!

Our Welding Expertise & Capabilities

Looking for a reliable metal welding service? At Shinco, we help you build strong, safe parts and assemblies, fast. From simple brackets to complex frames, we’ve got the tools and the team to do it right the first time. Ready to start? Contact us for a quick quote.

01.

MIG Welding

MIG is our go-to for speed and strength. We use a continuous wire and shielding gas to make clean, repeatable welds. It’s great for steel and stainless, and with pulse settings we handle aluminum too. If you need production volume or thicker sections, MIG delivers.

- Best for: frames, enclosures, fixtures, long seams

- Materials: carbon steel, stainless steel, aluminum

- Why it helps: fast cycle times and consistent results

ShincoFab runs MIG cells for both prototypes and production. Tell us your timeline and we’ll match the right process. Get a MIG quote today.

02.

TIG Welding

TIG gives you precision and beautiful welds. We use a non‑consumable tungsten electrode for tight control and smooth beads. It’s perfect for thin sheet, visible joints, and high cosmetic standards.

- Best for: thin gauges, cosmetic panels, small parts

- Materials: stainless steel, aluminum, titanium, copper

- Why it helps: minimal spatter, less distortion, top appearance

Our ShincoFab TIG team handles fine details with care. Have parts that must look great? Let’s talk TIG. Ask for a TIG sample or small run.

03.

Robotic Welding

Need repeatable quality at scale? Our robotic welding boosts speed and keeps every part the same. It’s ideal for long runs, complex fixtures, and tight tolerances.

- Best for: high-volume assemblies, repetitive welds

- Processes: MIG (primary), spot, custom sequences

- Why it helps: faster throughput, lower scrap, consistent quality

ShincoFab programs your weld path, tests samples, and ramps up quickly. Send your CAD and get a robotic plan and timeline.

04.

Laser and Specialized Welding

Some jobs need extra precision or unique methods. We offer laser welding for low heat input and narrow seams, plus FCAW and spot welding when conditions call for them.

- Laser Welding: super precise, low distortion, great for thin or cosmetic seams

- FCAW: strong welds on thicker steel, good in outdoor or windy conditions

- Spot Welding: fast, clean sheet metal joining without filler

ShincoFab will recommend the right method for your part and budget. Not sure what you need? Share your drawings and we’ll guide you.

05.

Materials & Thickness Ranges

We work across common metals and thicknesses. If you don’t see your spec, just ask.

- Carbon steel: 0.8–20 mm

- Stainless steel: 0.8–20 mm

- Aluminum: 0.8–15 mm

- Copper, brass, titanium: on request

Need More Help? Talk to ShincoFab. We’ll review your material, thickness, and finish needs, then suggest the best path.

Why Choose Our Metal Welding Service

Why we’re the right fit? This section shows exactly why our metal welding service stands out and how ShincoFab makes your job easier. If you’re comparing options, start here—and reach out to us anytime for a fast, no-pressure quote.

01.

Certified Quality and Full Documentation

When you need welds that pass audits the first time, we’ve got you. At ShincoFab, our metal welding service follows proven procedures with WPS and PQR on file, and welder qualifications maintained and traceable. We work to AWS (D1.1/D1.2/D1.6), ASME IX, and can support EN 1090 and ISO 9001-driven quality systems.

We provide material certs, heat numbers, weld maps, and inspection reports on request. Need testing? We offer VT, PT, MT, UT, and RT through trusted labs. This means fewer surprises, less rework, and faster approvals for your team. Tell us your compliance needs, and we’ll bake them into your quote. Contact ShincoFab to lock in the scope, standards, and paperwork you need.

02.

One-Stop Build: Cut, Form, Weld, Finish, Deliver

Skip the handoffs. With ShincoFab, you get laser cutting, CNC forming, tube bending, machining, custom fixtures, and assembly—plus the metal welding service itself—in one place. We also handle post‑weld grinding, bead blending, passivation, heat treatment, and finish options like powder coat, paint, anodize, and plating.

One project manager. One PO. One deadline. That’s how we keep your parts moving and your schedule safe. Fewer vendors means fewer delays and cleaner accountability. Send us your pack (CAD, prints, weld symbols), and we’ll return a single, clear quote with timeline and delivery plan. Reach out now to combine steps and save time.

03.

The Right Process For Your Metal and Thickness

Every job is different. We match process to part so you get strength, looks, and speed without paying for overkill. Our team runs MIG/MAG, TIG, FCAW, stick/SMAW, spot and stud welding, plus robotic and laser where it fits. We weld carbon steel, stainless steel, aluminum, copper/brass, titanium, and nickel alloys—from thin sheet to heavy plate.

ShincoFab’s fixtures and jigs control distortion, and we use pulse MIG and AC TIG for beautiful aluminum welds. For repeat parts, our robotic welding boosts consistency and cycle time. Tell us your material, thickness, and cosmetic needs. We’ll propose the best path and quote both manual and automated options so you can choose. Let’s talk through your use case today.

04.

Design Help That Cuts Cost, Risk, and Lead Time

Small choices in design make big differences in cost and quality. We help you pick the right joints (butt, lap, tee, corner, edge), call out realistic weld sizes, and use stitch or intermittent welds where allowed. ShincoFab’s DFM review flags heat‑sensitive zones, recommends fixtures, and improves access for stronger, cleaner welds.

We’ll simplify tight tolerances, reduce over‑spec’d welds, and suggest standard hardware or tabs where they make sense. Need samples first? We can run a prototype or weld coupons to prove the setup before you scale. Send your prints—our engineers will mark them up with clear, practical notes. Book a quick DFM review with our team and get a revised, cost‑saving quote.

05.

Speed, Capacity, and Reliable Delivery

Deadlines matter. We quote fast (often within 24–48 hours) and give realistic lead times you can plan around. Need to ramp? ShincoFab can scale from one-off prototypes to full production using robotic welding cells and balanced work cells. We support kits, Kanban, and scheduled releases for steady flow.

You’ll get updates you can trust and a single point of contact who owns your timelines. If you need an expedite, we’ll show you honest options and tradeoffs. Our metal welding service is built for repeatability, so your third order is as smooth as your first. Share your target dates—we’ll map a plan and lock in slots for you.

06.

Clean Cosmetics and Finish‑Ready Parts

When the part is customer-facing, looks matter. ShincoFab delivers cosmetic TIG, tight bead control, and careful blending for smooth seams. For stainless, we can passivate and clean heat tint. For aluminum, we manage heat input to avoid warp and keep a crisp look. Building tanks or housings?

We can leak test and document the results. Need them ready for paint or powder? We’ll prep surfaces, protect threads, and package parts so they arrive clean and ready to finish. Tell us your finish specs and we’ll weld to suit. Ask ShincoFab to include cosmetic samples or finish panels with your quote so you can approve before we run.

Trusted Metal Welding Service for Strong, Lasting Connections

Get your metal welding service done right the first time. We’re here to help you with expert welding solutions — whether it’s custom fabrication, repairs, or production runs. Let’s talk about your project, and ShincoFab will guide you every step of the way.

Frequently Asked Questions

Here you’ll find answers to the most common questions about our metal welding service. We want to make sure you feel confident and informed before you get started. If you have other questions, just reach out — we’re here to help.

What types of metals can you weld with your metal welding service?

We weld a wide range of metals like carbon steel, stainless steel, aluminum, brass, copper, and titanium. Just let us know what material you have, and we’ll recommend the best welding process for it.

Which welding methods do you use?

Our metal welding service uses popular methods like MIG, TIG, stick welding, spot welding, robotic welding, and laser welding. Each method suits different projects, so we’ll help you pick the one that fits your needs best.

How thick of metal can you weld?

Can you work from my drawings or CAD files?

How long does it take to get a quote and complete my metal welding project?

Do you provide quality certifications for your welding work?

Can I bring my own metal parts for welding?

What if I’m not sure which welding method is right for my project?

Do you offer post-welding services like grinding or finishing?

Yes, we can polish, grind, paint, powder coat, or apply other finishes to your welded parts. Just let us know your finish requirements when you contact us.

How can I trust your metal welding service for high-quality and reliable results?

Contact Us for Your Metal Welding Service Needs

Have questions or ready to start your project? We’re here to help with all your metal welding service needs. Whether you want advice on the best welding method, a custom quote, or simply want to talk through your project details, get in touch with us. Let’s work together to make sure your welding job is done right, on time, and within budget. Reach out today and experience a friendly, reliable partnership for your metal welding service.