Precision Laser Cutting Service

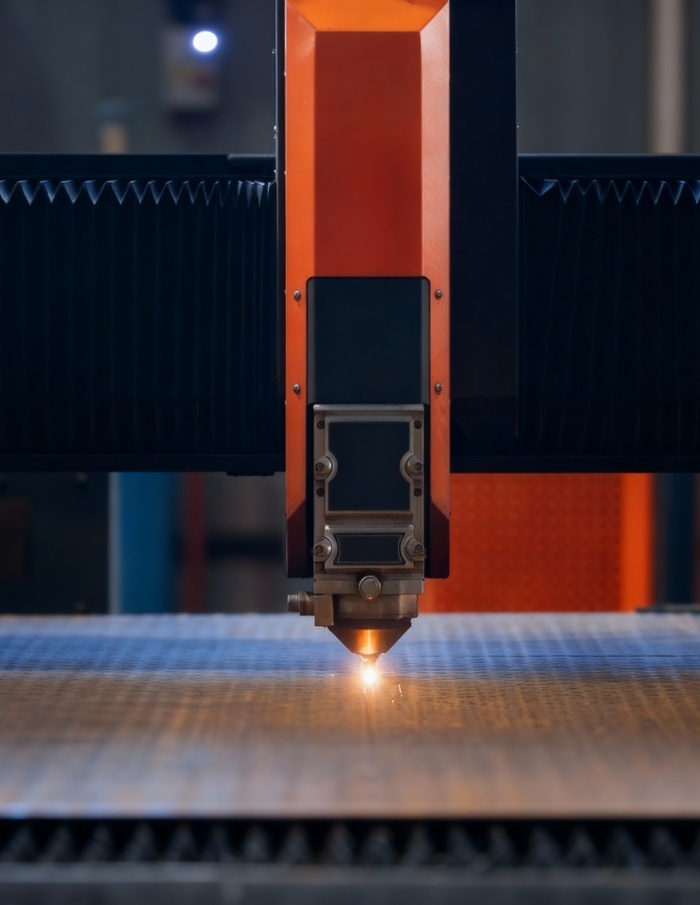

Our Laser Cutting Service delivers high-precision, rapid, and cost-effective cutting for metal, plastic, wood, and more. Get consistent quality and quick turnaround times to bring your prototypes and production parts to life with ease.

What is Laser Cutting and How Can It Help Your Project?

Laser cutting is a high-precision process that uses a powerful laser beam to cut, engrave, or mark materials. It delivers clean edges, excellent accuracy, and consistent quality—making it ideal for both rapid prototyping and production runs.

At ShincoFab, we specialize in laser-cutting a wide range of sheet materials. Whether you’re building a functional prototype or custom parts, our laser cutting service offers fast turnaround and detail that traditional tools simply can’t achieve.

This technology is perfect for product designers, engineers, and manufacturers who need high quality, quick delivery, and flexible production. By outsourcing your laser cutting to us, you can focus on design while our team handles the precision fabrication.

Available Metal Materials for Laser Cutting

We specialize in precision metal laser cutting, supporting a wide range of industrial and commercial metals. Our equipment handles both thin-gauge and thick materials with clean edges, high accuracy, and consistent quality.

Carbon Steel / Mild Steel

Strong, affordable, and widely used for structural parts and mechanical components. Ideal for general fabrication.

Stainless Steel (304 / 316 / etc.)

Corrosion-resistant with a clean finish, perfect for food equipment, medical parts, decoration, and outdoor applications.

Aluminum (Various Grades)

Lightweight, durable, and great for aerospace, automotive, and electronics. Provides smooth, fast cutting with minimal distortion.

Titanium

Ultra-strong, lightweight, and corrosion-resistant. Common in aerospace, medical devices, and high-performance parts.

Alloy Steel

Enhanced strength and hardness for industrial machinery, tools, and high-stress components.

Cold-Rolled & Hot-Rolled Steel Plates

CR steel offers smooth surface and precision; HR steel provides toughness for structural applications.

Galvanized Steel

Steel coated with zinc for excellent corrosion resistance. Suitable for HVAC, enclosures, and outdoor structures.

Copper/Brass

Highly conductive metal used for electrical parts and decorative applications. Requires precise laser control for clean cuts.

Our Sheet Metal Fabrication Capabilities

Our laser cutting service is designed to deliver accuracy, consistency, and efficiency—whether you need a single prototype or full-scale production.

01.

Advanced Laser Technologies

We use multiple laser types to support a wide range of materials and project requirements:

CO₂ lasers for wood, acrylic, leather, cardboard, and plastics

Fiber lasers for metals including stainless steel, carbon steel, aluminum, brass, and copper

Nd:YAG lasers for high-precision marking and cutting on specialty metals and reflective materials

02.

Material Size & Thickness Capacity

Our equipment supports large-format sheets and a full range of material thicknesses:

Metal (Fiber Laser):

- Stainless Steel: up to 20 mm

- Carbon Steel: up to 25 mm

- Aluminum: up to 12 mm

- Brass/Copper: up to 8 mm

Acrylic / Plastic (CO₂):

- Acrylic: up to 20 mm

- ABS / PVC / PETG: up to 10 mm

Max Sheet Size:

- Up to 3000 × 1500 mm (industry-standard large-format bed size)

03.

High Precision & Tight Tolerances

Our machines provide exceptional dimensional accuracy across both small parts and large sheets:

- Cutting tolerance up to ±0.1 mm

- Minimum kerf width: 0.1–0.2 mm depending on material

- Smooth edges with minimal to no post-processing

- Consistent performance for repeated production runs

04.

Smart Kerf & Nesting Optimization

We utilize professional CAD/CAM software to ensure accuracy and material efficiency:

- Automatic kerf compensation to maintain exact final dimensions

- Intelligent nesting algorithms that reduce waste and lower cost

- Optimized toolpaths for faster cutting and cleaner results

05.

Scalable for Any Production Stage

Whether you’re iterating quickly or scaling up, we provide flexible support:

- Rapid prototype turnaround

- Stable quality for small- to mid-batch orders

- High-efficiency production workflow for mass manufacturing

Why Choose Our Laser Cutting Service

Choosing the right manufacturing partner is essential for ensuring quality, reliability, and peace of mind. Here’s why customers trust us with their laser cutting projects:

01.

Certified Quality Management

We operate under strict ISO9001–based quality control, ensuring every part is produced with consistency, traceability, and documented inspection. You can rely on stable, repeatable results for both prototypes and production parts.

02.

Secure and Confidential File Handling

Your designs are protected with encrypted storage and internal confidentiality protocols. For sensitive or proprietary projects, we can sign NDAs and guarantee that your files will never be shared, resold, or used for any purpose other than your order.

03.

Experienced Engineering and Production Team

04.

Fast and Reliable Turnaround

Most orders are completed in two to four business days. For urgent needs, same-day or next-day production can often be arranged. Our streamlined workflow ensures your project moves quickly and smoothly from file to finished parts.

05.

Competitive Pricing with Volume Benefits

We provide transparent and cost-effective pricing designed for both small batches and large-volume production. Material nesting and optimized programming help reduce waste and keep your overall costs lower.

06.

Responsive Customer Support

Our support team is available to assist with design questions, material guidance, order status, and after-sales service. Whether through email, chat, or phone, you’ll receive fast responses and clear communication throughout the entire process.

Need Precision Metal Laser Cutting for Your Next Project?

Our advanced laser cutting technology delivers clean edges, tight tolerances, and consistent quality across all metal types. Whether you’re prototyping, customizing, or producing at scale, we’re ready to cut your design with accuracy and speed. Send us your file and get expert guidance within minutes.

Frequently Asked Questions

Have questions about our metal laser cutting services? This section covers everything you need to know— from supported materials and thicknesses to file preparation, pricing, accuracy, and delivery options. If you’re new to laser cutting or need guidance with your design, you’ll find clear answers here to help you move forward with confidence.

What metals can you laser cut?

We can process a wide range of metals including carbon steel, stainless steel, aluminum, galvanized steel, copper, brass, titanium, alloy steel, and both hot-rolled and cold-rolled plates. If you’re unsure whether your material is suitable, you can simply send us a photo or specification sheet and our team will help you confirm.

What thicknesses can you cut?

The maximum cutting thickness depends on each metal type. For example, carbon steel, stainless steel, and aluminum each have different thickness limits. If you share your material and thickness requirements with us, we will let you know immediately whether it falls within our capability.

What file formats do you accept?

We accept all common vector and CAD formats such as AI, EPS, SVG, DXF, DWG, and PDF. If you only have an image or sketch, we can assist in converting it into a proper cutting file.

Can you help optimize my design for laser cutting?

Yes. We can help refine kerf, spacing, tolerances, and overall file structure to ensure the final cut is clean, accurate, and cost-effective. Our team can also help you arrange parts more efficiently to reduce material waste.

Do you offer surface finishing and assembly services?

Absolutely. ShincoFab provides comprehensive finishing options including powder coating, anodizing, electroplating, brushing, polishing, and sandblasting. We also handle TIG/MIG welding, riveting, and mechanical assembly, ensuring complete, ready-to-use components.

What is your cutting accuracy?

Our equipment delivers high precision with tolerances typically around ±0.1–0.2 mm depending on the metal and thickness. This level of accuracy is suitable for parts that need precise assembly or tight mechanical fit.

What industries does ShincoFab serve?

Our sheet metal fabrication services support a wide range of industries including automotive, aerospace, electronics, medical equipment, construction, and industrial machinery. Whether you need enclosures, brackets, panels, or structural components — we can tailor solutions for your specific application.

What is your typical turnaround time?

Prototype orders are usually completed within 1–3 days, while small-batch production typically takes 3–5 days. Larger quantities may require additional time based on volume. If you have a deadline, we can also accommodate urgent orders.

Is there a minimum order quantity?

There is no strict MOQ. We accept single-piece prototypes, small production runs, and large-volume manufacturing.

How do you calculate pricing?

Our pricing considers several factors including material type and thickness, cutting time, complexity of the design, order quantity, and any required finishing services. If you send us your design file, we can provide an accurate quotation quickly.

Do you offer additional finishing services?

Yes. We provide several post-processing options including deburring, polishing, bending, forming, powder coating, anodizing, and other surface treatments. Simply let us know your finishing requirements when requesting a quote.

Do you provide materials, or can I supply my own?

We stock all commonly used metals for laser cutting. If you prefer to provide your own material, we can process it as long as it’s compatible with laser cutting and meets safety requirements.

Do you ship internationally?

Yes. We offer global shipping with reinforced packaging to ensure the metal parts arrive without scratches or deformation. We can also prepare export documentation for bulk shipments.

Can I visit your workshop or request a sample?

You are welcome to visit our production facility to see our capabilities in person. If you would like to evaluate our cutting quality before placing a larger order, we can provide a sample upon request.

Contact Us for Laser Cutting Services

Ready to start your laser cutting project or need help finalizing your design? Our team is here to assist with material selection, file preparation, pricing, and production planning. Whether it’s a single prototype or a full-scale order, reach out to us anytime—let’s bring your metal parts to life with precision and efficiency.