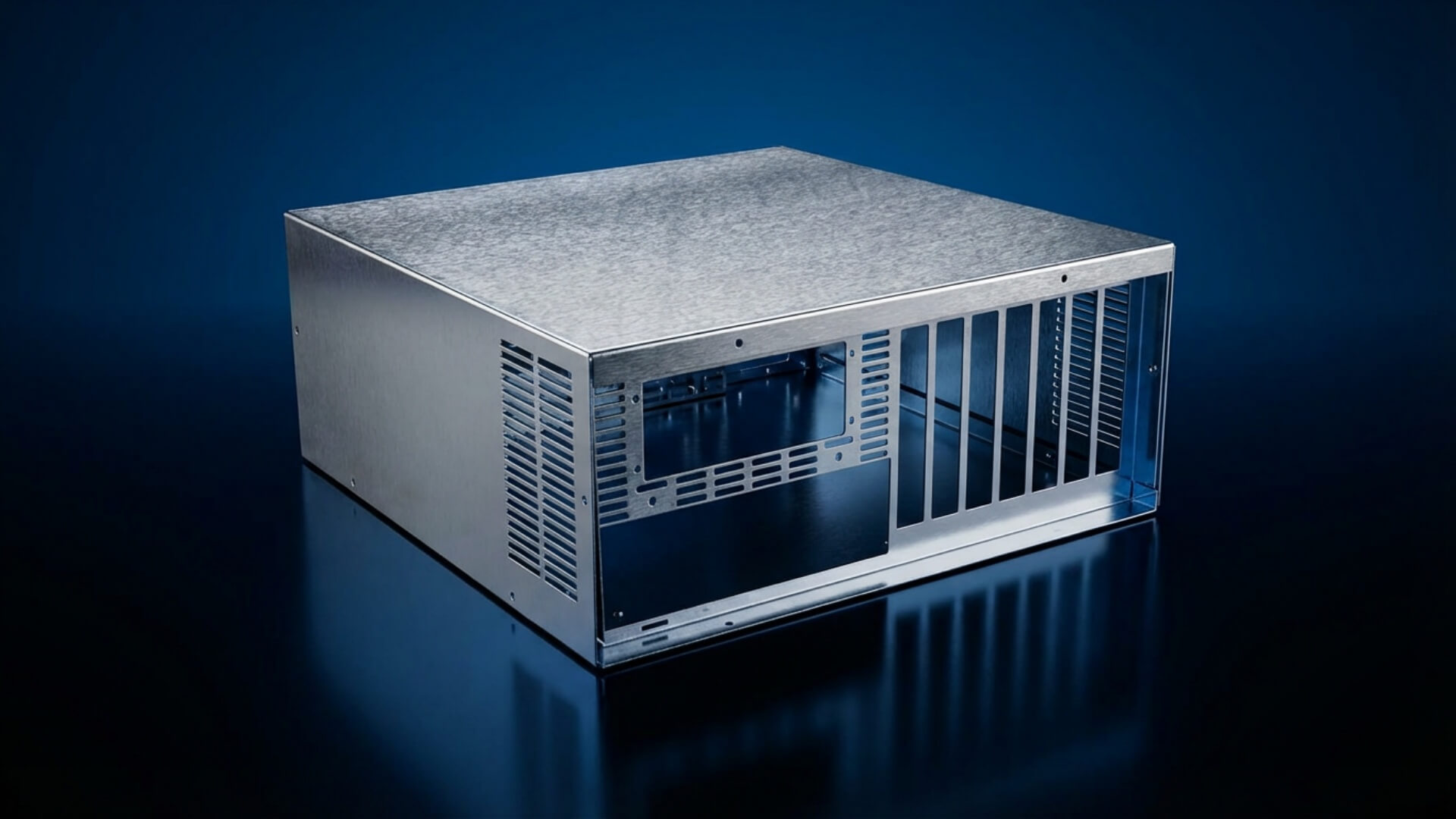

Custom Sheet Metal Card Cages

Don’t let tolerance stack-up ruin your assembly. ShincoFab delivers rugged, ready-to-integrate sheet metal card cages with flawless PCB alignment. From VME/VXI chassis to custom subracks, we handle complex punching, forming, and hardware insertion—ensuring your electronics fit perfectly every time.

What Are Custom Sheet Metal Card Cages?

At its core, a sheet metal card cage (or card rack) is a precision-engineered chassis designed to secure printed circuit boards (PCBs) and align them perfectly with a backplane or motherboard. But for mission-critical applications, it serves three vital functions beyond simple containment:

- Precision Alignment: It manages tolerance stack-up to ensure connectors engage without stress, preventing intermittent signal failures.

- Thermal Management: Through custom venting patterns and airflow guides, it facilitates efficient heat dissipation for dense electronics.

- Signal Integrity: It acts as a grounded shield, protecting sensitive components from EMI/RFI interference in noisy industrial environments.

Off-the-shelf subracks compel you to design your electronics around the box. Custom sheet metal fabrication allows the box to be built around your electronics. Whether you need non-standard card guides, specific connector cutouts, or integrated I/O panels, custom fabrication ensures your enclosure fits your technology, not the other way around.

Our Specific Fabrication Capabilities for Card Cages

At ShincoFab, we bridge the gap between prototype shop agility and production house consistency. Our facility is optimized for high-mix, low-to-mid volume manufacturing. Whether you need a single First Article Inspection (FAI) unit for validation or a monthly run of 5,000 ruggedized subracks, our process ensures strict adherence to your GD&T specifications.

Specialized Manufacturing Workflow for Card Cages

- Precision Cutting (Laser & CNC Punching): We utilize fiber lasers and turret punches to create intricate hexagon/honeycomb ventilation patterns and connector cutouts with burr-free edges. This ensures maximum airflow and safe handling for assemblers.

- CNC Forming & Bending: Using multi-axis back gauges, we maintain critical dimensions between card guides. We guarantee the structural orthogonality required for PCBs to slide in smoothly without binding.

- Hardware Insertion: Automated press-fit installation of PEM® nuts, standoffs, and studs. We verify pull-out forces to ensure your components stay secure, even under vibration.

- Welding & Joining: From spot welding for EMI gaskets to full TIG seam welding for rugged MIL-spec chassis, our certified welders ensure structural rigidity.

- Surface Finishing: We offer in-house and partnered finishing including Chromate Conversion (Alodine) for conductivity, Anodizing (Type II/III) for durability, and Powder Coating for aesthetics and insulation.

Material Expertise

We stock and source premium-grade metals essential for electronic packaging:

- Aluminum (5052-H32 / 6061-T6): Ideal for thermal dissipation and lightweight aerospace applications.

- Steel (CRS / SECC / EG): For superior magnetic shielding and structural strength in server racks.

- Copper & Brass: Used for grounding busbars and specific contact applications.

Speed & Reliability

- Standard Lead Time: 10-15 days for tooling and samples; 3-4 weeks for production runs.

- Expedited Services: Available for urgent NPI (New Product Introduction) deadlines.

- Quality & Inspection: 100% dimensional inspection on critical features before shipping.

Customization Options & Features

We don’t force you into a catalog standard. ShincoFab offers a complete range of customization options to ensure your card cage meets specific mechanical, thermal, and cosmetic requirements.

Card Guide Integration

The interface between your PCB and the chassis is critical. We support various mounting styles:

- Plastic Guides: Snap-in or bolted options for cost-effective, low-friction insertion.

- Metal Guides: Machined or formed aluminum for high heat dissipation and rugged grounding.

- Anti-Vibration / Locking Guides: For high-shock environments (MIL-spec applications).

- Keying: Custom keying to prevent incorrect board insertion.

Chassis Construction

Choose the architecture that best fits your volume and strength requirements:

- Precision Bent Sheet Metal: Best for custom sizes, lower tooling costs, and complex cutouts. Ideal for prototypes and low-to-mid volume.

- Aluminum Extrusion Profiles: Best for high structural rigidity and aesthetic appeal on standard widths (e.g., 19″ rackmounts).

- Hybrid Construction: Combining extruded rails with sheet metal side plates for the best of both worlds.

Surface Finishes & Protection

We ensure your card cages are conductive where needed and durable everywhere else:

- Conductive Finishes: Clear Chromate (Alodine/Surtec 650) for electrical grounding and corrosion resistance.

- Anodizing: Type II (Color) or Type III (Hardcoat) for scratch resistance and dielectric insulation.

- Powder Coating: Durable, textured finishes in any RAL color to match your corporate branding.

- Plating: Zinc, Nickel, or Tin plating for steel chassis.

Critical Features: Thermal & EMI

- Ventilation: Custom honeycomb, slot, or perforated patterns optimized for airflow simulations (CFD).

- EMI/RFI Shielding: Integrated beryllium copper gaskets, conductive foams, and closed-corner welding to minimize leakage.

- Cable Management: Integrated tie-down points, routing holes with grommets, and strain relief features.

Front Panels & Identification

- Custom Cutouts: Precision milling for LEDs, switches, and D-sub/circular connectors.

- Marking: High-resolution Silk Screening, Laser Engraving, or Digital UV Printing for labels and logos.

- Hardware: Captive screws, ejector handles (ejectors/injectors) for easy board removal (Hot-Swap support).

Design for Manufacturing (DFM) & Engineering Support

A card cage that looks perfect in SolidWorks doesn’t always translate flawlessly to the press brake. At ShincoFab, we don’t just blindly execute your CAD files; we analyze them. Our engineering team acts as an extension of your R&D department, optimizing your designs to reduce unit costs, eliminate tooling bottlenecks, and ensure precise fitment.

Real-World DFM Optimization

We scan every drawing for common fabrication pitfalls. Here is how we improve your design:

- Bend Reliefs & Notching: We ensure proper relief cuts are in place to prevent material tearing or bulging at the corners—critical for maintaining card guide parallelisim.

- Hems & Safety Edges: We recommend hemming specific edges not just for rigidity, but to protect cabling from insulation damage and keep assembly workers safe from cuts.

- Welding vs. Fastening: We advise when to switch from continuous welding (high distortion risk) to spot welding or riveting to maintain tighter dimensional tolerances.

- Tolerance Rationalization: We challenge “over-dimensioning.” If a feature doesn’t need +/-0.05mm, we’ll tell you. Loosening non-critical tolerances can reduce your costs by 20-30%.

Agile Prototyping & Iteration

Product development is rarely a straight line.

- Rapid Feedback Loop: Send us your preliminary STP/STEP files. We provide manufacturability feedback before you finalize the design.

- Handling Revisions: Need to move a connector cutout 2mm to the left after the first prototype? No problem. Our digital workflow allows for rapid design updates without massive tooling setup fees.

Full Lifecycle Support

- Pre-Order: Free DFM report and cost-saving suggestions.

- During Production: Real-time resolving of material issues.

- Post-Delivery: Assembly troubleshooting support.

Get a Production-Quality Prototype in As Little As 7 Days

Risk-free evaluation before you commit to volume. Test your card cage’s PCB fitment, thermal efficiency, and EMI shielding in the real world. No minimum order quantity, full DFM analysis included, and shipped via DHL/FedEx for immediate testing on your bench.

Frequently Asked Questions

Don’t let uncertain details delay your prototype build. We’ve compiled the most frequent questions from engineers and procurement managers regarding our fabrication process, lead times, and shipping terms.

What file formats do I need to send for a quote?

We prefer 3D formats like STEP (.stp) or SAT for precise bending calculations. For flat patterns or silk screening artwork, DXF or AI files are best. If you only have PDF drawings or rough sketches, our engineering team can assist with CAD modeling for a fee.

What are your standard tolerances for card cages?

For CNC punching and laser cutting, we hold +/-0.1mm. For bent sheet metal dimensions (form-to-form), our standard is +/-0.2mm to +/-0.3mm depending on material thickness. Critical features (like card guide spacing) can be held tighter upon request. We recommend defining critical dimensions (CTQ) in your drawings.

Do you handle hardware insertion and sub-assembly?

Yes. We don’t just ship bent metal. We install all PEM® fasteners (nuts, studs, standoffs), riveted card guides, handles, and ejectors. We can ship the cages fully assembled or as flat-packed kits to save on shipping costs.

How do you handle EMI/RFI shielding requirements?

We apply shielding through specific fabrication techniques: using conductive finishes (like Alodine/Surtec 650 or Zinc plating), designing overlapping seams, and installing beryllium copper gaskets or conductive foam. Please specify your attenuation requirements, and we will recommend the best construction method.

What is your typical lead time for prototypes vs. production?

- Prototypes: 7-10 days after design confirmation.

- Production (100-500 units): 3-4 weeks.

- Expedited Service: Available for urgent NPI builds. We control the entire process in-house, which allows us to compress timelines when necessary.

Is my Intellectual Property (IP) safe with ShincoFab?

Absolutely. We work with global Tier-1 electronics and defense companies and strictly adhere to NDA (Non-Disclosure Agreement) protocols. Your designs are never shared with third parties or used for other customers. We are happy to sign your NDA before viewing any files.

Do you have a Minimum Order Quantity (MOQ)?

Technically, No. We act as a scalable partner. While unit costs are higher for a quantity of 1 or 5 due to setup amortization, we are fully equipped to handle single prototype runs. Price breaks typically start improving significantly at 50+ units.

How do you handle international shipping and Incoterms?

We ship daily to North America and Europe. For prototypes and small batches, we use DHL/FedEx/UPS (DAP – Delivered at Place). For heavy palletized production runs, we handle Air Freight or Sea Freight (FOB/DDP) directly to your warehouse.

Get Your Fabrication Quote & DFM Review Within 24 Hours

Ready to move forward? Upload your STEP or DXF files for a secure, confidential analysis. Our engineering team will review your specs for manufacturability and provide a firm cost estimate, no hidden fees, no obligations.