Sheet Metal Enclosure

Discover precision-engineered sheet metal enclosures designed for durability, customization, and rapid delivery. Protect your electronics with our versatile sheet metal enclosures crafted to meet industry standards and exact specifications.

Why Sheet Metal Enclosures Matter

A sheet metal enclosure is more than just a housing for your components; it is the face of your brand and the fortress for your technology. Beyond ensuring a premium first impression, a well-engineered enclosure is critical for product longevity—providing essential EMI shielding, efficient heat dissipation, and rugged structural support that protects against dust and impact. It connects your users to your product with a sense of quality, giving you the confidence that your technology remains safe in any environment.

At ShincoFab, we translate these requirements into reality with precision. We understand that you aren’t just buying metal parts; you are investing in peace of mind. Our custom manufacturing services ensure that whether your product faces harsh industrial conditions or sits on a consumer’s desk, it is built to perform flawlessly. Let ShincoFab handle the manufacturing complexities so you can focus on your core innovation.

Key Considerations for Sheet Metal Enclosure Design

Transforming a CAD model into a physical sheet metal enclosure requires bridging the gap between digital perfection and manufacturing reality. At ShincoFab, our engineering team applies advanced Design for Manufacturability (DFM) principles to ensure your designs are not only functional but also optimized for production. By partnering with us early in the design phase, you can prevent costly revisions, significantly reduce tooling costs, and accelerate your time-to-market.

Consistent Bend Radii

Aim to keep internal bend radii consistent across your entire design, ideally matching the material thickness. Using a single radius throughout the enclosure means our press brakes don’t need to pause to change tooling setups during production. This simple standardization maximizes structural strength while directly lowering your manufacturing costs and shortening lead times.

Mind the "Deformation Zone"

Holes and slots placed too close to a bend line will inevitably stretch and warp during the forming process. To ensure your mounting holes stay perfectly round and components fit as intended, we recommend keeping all features at a distance of at least 3 to 4 times the material thickness away from any bend line. This preserves the integrity of both the detailed features and the bend itself.

Allowance for Assembly Tools

A common oversight in compact enclosure design is creating a sturdy box that is physically impossible to assemble manually. Always verify that there is sufficient clearance inside corners and deep flanges for screwdrivers, wrenches, or welding guns to reach fasteners. Designing with “tool access” in mind ensures that the final assembly at ShincoFab (or at your facility) is smooth and efficient.

Choosing Your Materials & Finishes

Selecting the right material is about finding the perfect balance between strength, weight, environmental resistance, and cost. At ShincoFab, we stock a wide variety of industrial-grade metals to match your specific application. Whether you are building a rugged outdoor telecommunications box or a sleek medical device, we have the raw materials and the finishing capabilities to make it happen.

Core Material Options

Aluminum (5052 / 6061)

Ideal for weight-sensitive applications and electronics requiring heat dissipation. Aluminum offers excellent natural corrosion resistance and strength-to-weight ratio.

- Best For: Aerospace, portable devices, electronic chassis.

- Pros: Lightweight, non-magnetic, heat-dissipating.

Cold Rolled Steel (CRS / SECC)

The gold standard for indoor enclosures. Steel provides superior tensile strength and durability at a lower cost point. It requires plating or coating to prevent rust, making it a perfect canvas for powder coating.

- Best For: Industrial cabinets, server racks, indoor consoles.

- Pros: High strength, cost-efficient, weldable.

Stainless Steel (304 / 316)

When hygiene or harsh environments are factors, Stainless Steel is the answer. It requires no additional coating to resist rust and chemicals, offering a premium, professional aesthetic.

- Best For: Medical environments, food processing, marine/outdoor use.

- Pros: Chemical resistance, hygienic, high durability.

Surface Finishes

Powder Coating

A dry finishing process available in unlimited colors and textures (matte, gloss, sandtex). Offers superior protection against scratches and chipping compared to wet paint.

Anodizing

Specifically for aluminum. It hardens the surface and adds a metallic color finish (Clear, Black, Blue) while keeping the metal non-conductive.

Chromate / Zinc Plating

Provides a conductive coating for steel and aluminum parts that require electrical grounding (EMI shielding) while offering basic corrosion protection.

Direct Branding

We apply your logo, labels, and port diagrams directly onto the enclosure, giving it a finished product look and eliminating the need for adhesive stickers.

Secondary Operations

Hardware Insertion

We pre-install PEM® fasteners, standoffs, and studs using automated insertion presses. This drastically simplifies your final PCB and component assembly.

Precision Welding

From spot welding for structural rigidity to full seam welding for watertight corners (TIG/MIG), we ensure your enclosure meets all strength requirements.

Sub-Assembly

We go beyond flat parts. We can handle mechanical assembly, gasket installation, and riveting before shipping, delivering a plug-and-play unit to your facility.

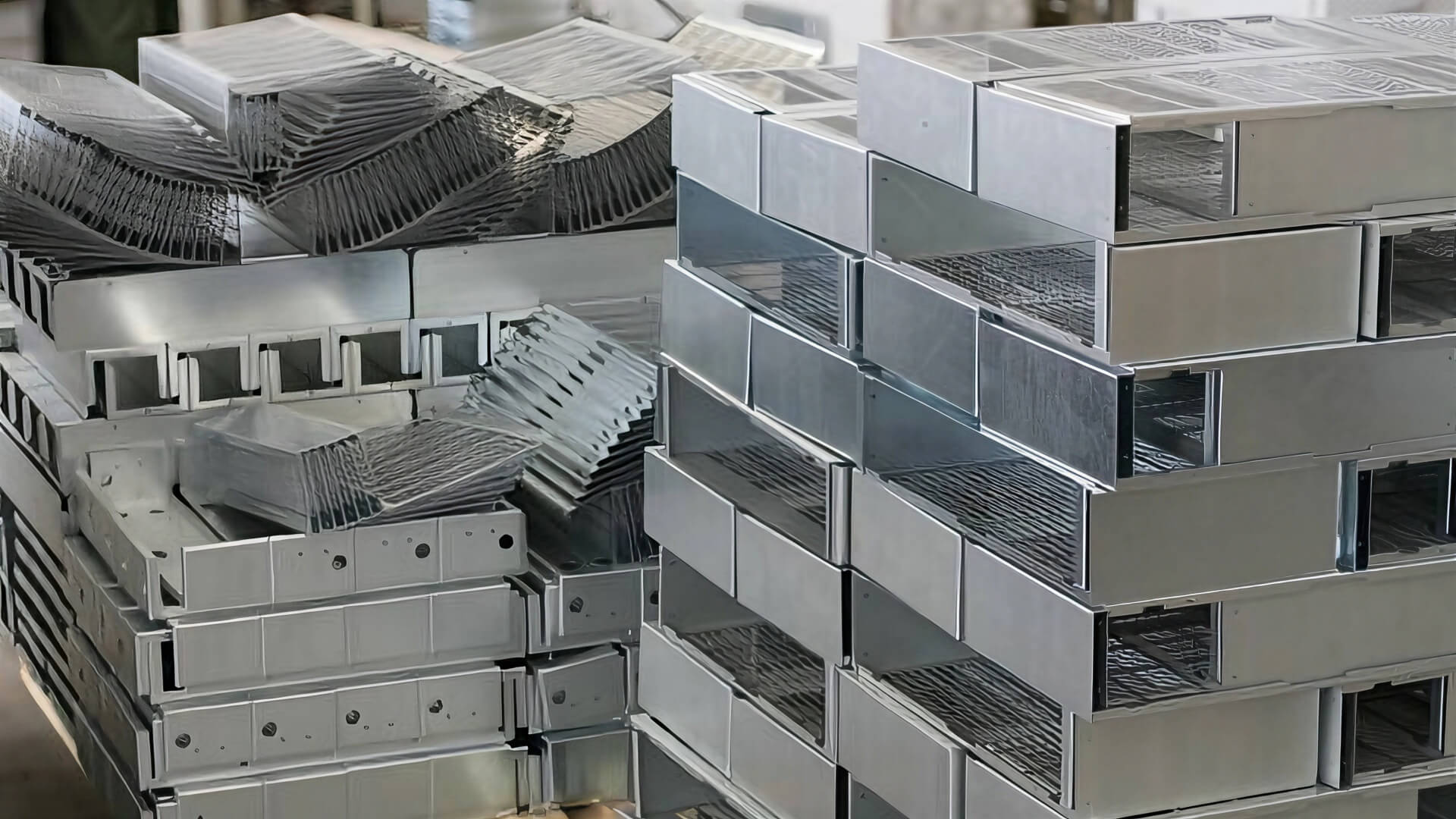

Sheet Metal Enclosure Products We Manufacture

Explore the versatile range of sheet metal enclosures produced at ShincoFab. We transform raw metal into high-precision housings for every industry. Whether you need a standard 1U rackmount chassis or a complex custom NEMA enclosure, our engineering and production teams deliver solutions that fit your design perfectly.

Rackmount Enclosures

Industrial NEMA / Electrical Cabinets

Electronics Chassis

Consoles & HMI Control Panels

Ready to Bring Your Enclosure Design to Life?

Don't let manufacturing bottlenecks slow down your innovation. Our team is standing by with the materials, machinery, and expertise to deliver your custom enclosures on time. Have questions before starting? We have the answers ready below.

Frequently Asked Questions

Got questions about your next project? We are here to streamline the process. Below, we address the top inquiries regarding our custom sheet metal enclosures, covering key details on design constraints, material options, and delivery schedules so you can move forward with confidence.

Why choose a sheet metal enclosure over plastic or molded options?

Sheet metal offers superior durability, EMI/RFI shielding, and better heat dissipation compared to plastic. It requires no expensive molds tooling, making it the most cost-effective choice for custom prototypes and low-to-medium volume production runs.

What is your Minimum Order Quantity (MOQ)?

At ShincoFab, we are flexible. We handle everything from single prototypes (MOQ 1) to high-volume production runs of thousands. We specialize in helping you transition seamlessly from concept to mass production.

What file formats do I need to send for a quote?

For the fastest and most accurate quote, please provide a 3D CAD model (STEP, STP, or IGES format). If you require threaded holes or specific tight tolerances, a 2D PDF drawing with callouts is also highly recommended.

How long does it take to manufacture a custom enclosure?

We pride ourselves on speed. Standard prototypes ships in 3-7 days depending on finish requirements. For production runs, lead times typically range from 2-3 weeks. We also offer expedited services for urgent project deadlines.

How can I reduce the manufacturing cost of my design?

To keep costs down, try to use standard bend radii, avoid tight tolerances on non-critical features, and stick to stock material gauges. Our engineering team can provide a free DFM review to highlight specific cost-saving opportunities in your design.

Can you manufacture enclosures with waterproof (IP) ratings?

Yes. We can design and manufacture enclosures to meet specific IP65, IP66, or NEMA 4 ratings. This typically involves sem-welded corners, customized gasketing, and specialized finishes to ensure protection against dust and water ingress.

Which material is best for my specific environment?

For indoor use, Cold Rolled Steel is strong and cost-effective. For lightweight or heat-sensitive electronics, Aluminum (5052/6061) is ideal. For outdoor or medical use requiring hygiene and rust resistance, Stainless Steel (304/316) is the superior choice.

Do you offer assembly services (installing fasteners, hinges, etc.)?

Absolutely. We deliver ready-to-use enclosures. This includes installing PEM® fasteners, standoffs, hinges, and even basic mechanical sub-assembly. We can also handle silk screening or laser engraving for your branding.

I don't have a CAD file, only a sketch. Can you still help?

Yes, we can. While 3D files are faster, our design team can work from hand sketches, sample parts, or detailed descriptions to create the necessary CAD models for manufacturing.

Contact Us About Your Sheet Metal Enclosure Needs

Got questions or ready to get started with your sheet metal enclosure? We’re here to help you find the right solution that fits your exact needs. Whether you want a quick quote, design advice, or just want to chat about your project, reach out anytime.