Blog

The ShincoFab blog is dedicated to building a comprehensive knowledge base for sheet metal fabrication. No corporate news, just hard-core process analysis. Whether you need to understand the forming logic of complex structures or the corrosion resistance of different finishes, explore expert-level articles that answer all your questions about metal manufacturing.

Welding vs. Riveting: Which Is Better for Metal Fabrication Projects?

You have two pieces of metal. You need them to stay stuck together. Now you have a choice to make: melt them together (welding) or pin them together (riveting). I’ve spent years in the shop fabricating everything from heavy steel frames to delicate aluminum panels. I know from experience that picking the wrong method can

Spot Welding 101: Machine Setup & How to Get Strong Welds

Sick of blowing holes in thin sheet metal with your MIG welder? I’ve been there. I spent three weekends trying to patch a floor pan on a ‘65 Mustang, chasing burn-throughs with my MIG torch until I wanted to scream. After years of fabricating panels, I learned that sometimes the best tool wasn’t an arc

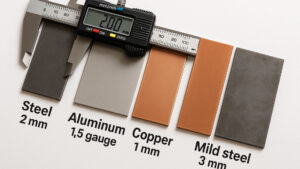

Sheet Metal Thickness & Gauge Guide: Charts, Standards, and Selection Strategies

When you are designing for sheet metal, choosing the right material thickness is one of the most important decisions you will make. This isn’t just a minor detail—it effectively sets the foundation for your entire project. This single variable determines three things: how strong your part is, how much it weighs, and what it costs

5052 vs. 6061 vs. 7075: How to Choose the Right Aluminum for Fabrication

Choosing the right grade of aluminum for your project is critical. To the untrained eye, every sheet of aluminum looks like the exact same piece of “silver metal.” But if you pick the wrong one, the consequences for your finished part can be expensive and irreversible. Think about the trade-offs: an alloy engineered for aerospace