Tube Laser Cutting Services

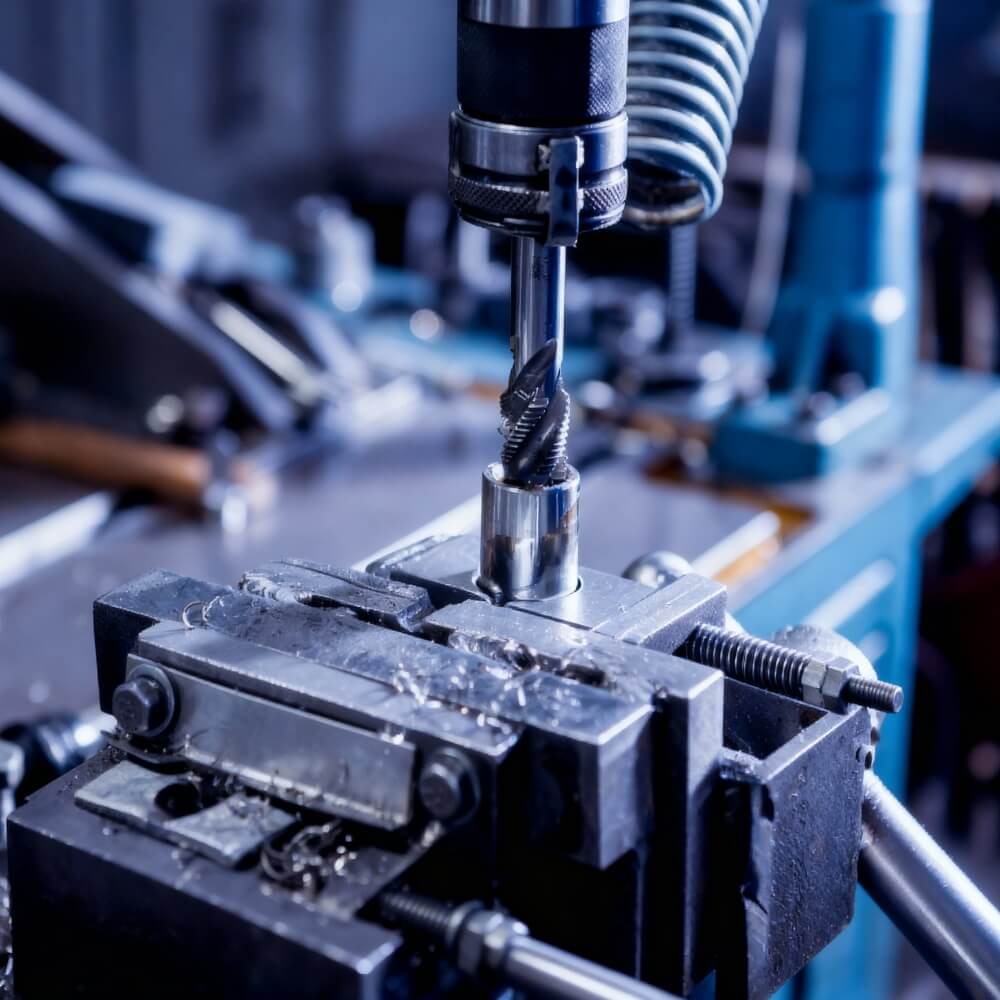

Experience fast, accurate, and cost-effective tube laser cutting services with advanced technology. From prototyping to production, our tube laser cutting services deliver clean, complex cuts across diverse metals and shapes, ensuring minimal waste and on-time delivery.

What is Tube Laser Cutting Services?

Tube laser cutting services are a way to cut metal tubes and pipes with a powerful laser. This process lets you create precise shapes, holes, and designs on round, square, or rectangular tubes quickly and cleanly. It’s perfect when you need parts that fit just right with smooth edges and minimal waste. The laser moves with high accuracy, so you get exactly what you want every time.

At ShincoFab, we offer top-quality tube laser cutting services that make your project easier and faster. You can send us your designs, and we’ll cut your tubes with the latest laser machines that handle all common metals like stainless steel, aluminum, and carbon steel. We pride ourselves on fast turnaround times and clear pricing—no surprises.

What sets us apart? We care about your needs and provide expert advice whenever you want it. Our team helps you with complex shapes or special sizes, and we handle everything from prototypes to large production runs. Plus, we keep communication simple and friendly because we know how important it is to get your parts right and on time.

Ready to get perfect cuts for your metal tubes? Contact ShincoFab today and let’s bring your ideas to life with our reliable tube laser cutting services!

Our Capabilities on Sizes, Materials & Tolerances

Get clear on what our tube laser cutting services can do. At Shinco, we make it easy to see if your parts fit our window. If you’re on the edge or have something unique, message us and we’ll review your prints right away.

01.

Tube Dimensions

Size Range

- Round tube OD 0.50″ – 10.00″

- Square tube 0.50″ – 8.00″

- Rectangular tube short side 0.50″ – 6.00″; long side up to 10.00″

Length Capacity

- Finished part length up to 20 ft (6.1 m)

- Raw stock (auto load) up to 28 ft (8.5 m)

- Minimum part length 2.0″ (shorter by request with fixture review)

Wall Thickness

- Carbon/mild steel 0.035″ – 0.500″ standard; up to 0.625″ on round with review

- Stainless (304/316) 0.035″ – 0.500″

- Aluminum (5052/6061) 0.035″ – 0.375″

- Copper/Brass 0.040″ – 0.250″

02.

Shapes & Profiles

We cut a wide range of tube shapes and open profiles:

- Round, square, rectangular

- Oval and flat-oval

- Angle, channel, and open profiles

- Special shapes and extrusions (send us a print for review)

03.

Materials We Process

- Carbon steel A500, A513 (HREW/CREW/DOM), mild steel grades

- Alloy steel 4130/4140 (seamless and CDS)

- Stainless steel 304/304L, 316/316L (welded and seamless)

- Aluminum 5052, 6061, 6063 (extruded/drawn)

- Copper and brass

- Titanium and other alloys on request

Don’t see your grade? Ask ShincoFab — we also run customer-supplied material.

04.

Tolerances & Accuracy

Standard Tolerances

- Feature-to-feature ±0.010″ typical

- Hole location ±0.010″ typical

- Overall length ±0.010″ to ±0.015″ (depends on length)

- Repeatability process-controlled; tighter on request with GD&T callouts

Feature Specifications

- Minimum feature size ≥ material thickness, or 0.060″ minimum (whichever is larger)

- Kerf width approximately 0.008″–0.020″ depending on material and thickness

- Bevel cutting up to 45° for weld prep and miters

05.

Cutting Quality & Features

Edge Quality & Finish

- Clean, burr-minimized edges with nitrogen or oxygen assist

- Small witness at lead-in/lead-out may be visible, ShincoFab can remove upon request

- Heat tint on some alloys is normal; finishing options available

Holes, Slots & Features

- Through-holes as small as 1× material thickness recommended

- Tabs/slots for self-fixturing assemblies

- Countersinks, bevels, and etching/marking available

- Tapping available on request (send thread callouts)

06.

Inspection & QA

- Material certs and lot traceability on request

- In-process seam detection for welded tube

- First Article and inspection reports available

Have a special profile, thick wall, or very small features? Send your file to Shinco and we’ll verify fit, tolerances, and best process. Let’s make sure your parts run right the first time.

Why Choose Our Tube Laser Cutting Services

Why you’ll want to work with ShincoFab for tube laser cutting services. This section explains what sets us apart and how we help you hit your goals with less stress. Ready to move fast? Contact us now to get a quick, accurate quote and DFM feedback.

01.

Fast, Accurate Quoting and DFM You Can Trust

You shouldn’t wait days to learn if your part is buildable. With ShincoFab, you get fast pricing and practical DFM guidance up front. Upload your CAD and we’ll flag risks early, like thin walls, tiny slots, tight hole-to-edge distances, and bend reliefs that could tear. We’ll suggest better tab-and-slot sizes, kerf-aware features, weld-prep geometry, and tapping allowances that fit your spec.

Our quoting nests parts to reduce waste, so your price reflects real material use and run time. What we quote is what you pay. No surprises, no guesswork. Want a sanity check before ordering? Ask us for a quick design review. We’ll walk your model with you and recommend clean fixes. Send your STEP, STP, DXF, DWG, or native files and let’s get started today.

02.

Precision and Repeatability Built in

You need parts that fit the first time. At ShincoFab, precision is standard. We run modern fiber tube lasers and 5-axis heads to hold tight, repeatable cuts with clean edges and minimal heat. Bevel cuts, miters, slots, and fishmouths are crisp and consistent, job after job. We use smart chucking and seam detection to place features exactly where you want them.

Our QA flow includes first-article checks, in-process inspection, and final verification on critical dimensions. Need extra documentation? We can provide inspection reports, material certs, and labeled bag-and-tag kits so assembly is smooth. The result is simple: parts that line up, weld faster, and build right the first time. Tell us your tolerance needs and we’ll match the process to your spec. Ask for a sample or pilot run to prove it out.

03.

Big Range of Shapes, Sizes, and Materials

Your work isn’t one-size-fits-all. Neither are we. ShincoFab’s tube laser cutting services handle round, square, and rectangular tube, plus open profiles like angle, channel, and more. We process common metals like carbon steel (A513/DOM), stainless steel (304/316), aluminum (6061), and, on request, copper and brass. Need special features? We do bevels and miters for tight joints, slots for plug welds, tabs for self-fixturing, countersinks, etching, and part marking for traceability.

Our automated loaders keep long stock moving so your schedule stays on track. Have a complex cut pattern or a mix of sizes? We coordinate runs to maximize yield and reduce scrap. If you’re unsure about material or wall thickness, we’ll steer you to the best option for strength, finish, and cost. Share your print and we’ll recommend the right process.

04.

Assembly-Ready Parts That Cut Your Total Cost

Cutting is only part of the job. The real win is faster assembly. At ShincoFab, we design and cut for fit-up to save you time on the floor. Weld-prep bevels, clean miters, and tab-and-slot joints make fixtures simple and welds fast. We support flow drilling and tapping, so holes are ready for hardware without extra machining. That means fewer steps, fewer setups, and fewer chances for error.

We can kit, label, and package parts by assembly so your team can build right from the box. Many customers see major time savings by letting us tune joint geometry and reduce weld length. Send us your current design and we’ll suggest changes that lower cost without hurting strength. Want to try it on one cell first? We’ll run a pilot and show you the difference. Ask us for an assembly-ready quote today.

05.

Speed, Capacity, and Reliable Delivery

Deadlines matter. We plan for them. Shinco runs high-throughput tube laser cutting services with automation that keeps your parts moving. Need quick-turn prototypes? We slot small runs fast so you can test and iterate. Need a steady drumbeat of production? We schedule capacity and provide clear lead times with status updates. Have a spike in demand? We scale and, when needed, tap trusted partners to keep your dates safe.

We ship nationwide and handle careful packaging so parts arrive clean and protected. If you have a hard stop on site, tell us early—we’ll build the plan with you, including split shipments or phased deliveries. Ask about expedite options if you’re up against it. Message us now and we’ll map out the fastest, safest path to your PO date.

06.

People You Can Reach, Experts You Can Trust

Great machines need great people. At ShincoFab, you get a real team: a dedicated project lead and responsive engineers who speak plainly and act fast. We’ll help you choose materials, set tolerances, and design features that build better. Have a last-minute change? Send the rev; we’ll confirm impacts and keep you moving. We work under NDA, support common CAD formats, and keep your data secure.

Want the same parts again in six months? We keep run books and settings so reorders are simple and consistent. If something isn’t perfect, we make it right—fast. Let’s talk through your print, your timeline, and your budget. Just contact us and we’ll get you a plan today.

Precision You Can Trust with Our Tube Laser Cutting Services

Ready to get your project moving? Our tube laser cutting services deliver fast, exact cuts that fit your needs perfectly. Whether it’s prototypesor production runs, we make it easy for you to get quality parts on timeand within budget.

Frequently Asked Questions

Looking for answers about our tube laser cutting services? You’re in the right place. Below are some common questions we hear from folks wanting to learn how tube laser cutting can help their projects. If you don’t see your question here, just reach out—we’re happy to help!

What exactly is tube laser cutting?

What materials can be cut with your tube laser cutting service?

We work with a wide range of metals, including stainless steel, aluminum, mild steel, brass, copper, and some alloys. If you have a special material in mind, just ask!

How accurate is the laser cutting process?

What are the size limits for tubes you can cut?

Can you cut complex shapes and holes in tubes?

How fast can I get my tube laser cut parts?

We know timing is critical. Typical lead times range from 1 to 7 days depending on your project size and complexity. Reach out with your files, and we’ll give you an exact turnaround time.

Is there a minimum or maximum order quantity?

Not usually. We can handle everything from a single prototype piece to large production runs. Just send us your project details to get started.

What file types are accepted for tube laser cutting quotes?

We accept most common 3D CAD files like STEP, STL, IGES, as well as 2D formats like DXF and DWG. If you’re unsure, just ask—we’ll guide you through what works best.

What happens if I don’t have a detailed CAD file?

How do you handle quality control?

Are there benefits to choosing tube laser cutting over traditional cutting methods?

Can you help me optimize my tube design for manufacturing?

Definitely. We offer design for manufacturability (DFM) feedback to help you get the most out of your tube laser cutting project. Reach out for a free consultation!

If you still have questions or want to discuss your project, contact us today. We’re here to help you get the best from your tube laser cutting needs!

Contact Us for Tube Laser Cutting Services

Got questions or ready to start your project? Our friendly team is here to help with all your tube laser cutting services needs. Whether you have a unique design, need a quick quote, or want advice on materials and sizes, just reach out. We make it easy and fast to get the precise tube cutting support you need—no hassle, no fuss. Send us a message or give us a call today, and let’s make your tube laser cutting project a success!