Sheet Metal Bending Services

Discover our Sheet Metal Bending Services designed to deliver high-precision, cost-effective metal forming solutions. We handle diverse materials and complex bends with fast turnaround, ensuring your components meet exact specifications and support your production goals.

What is Sheet Metal Bending Services?

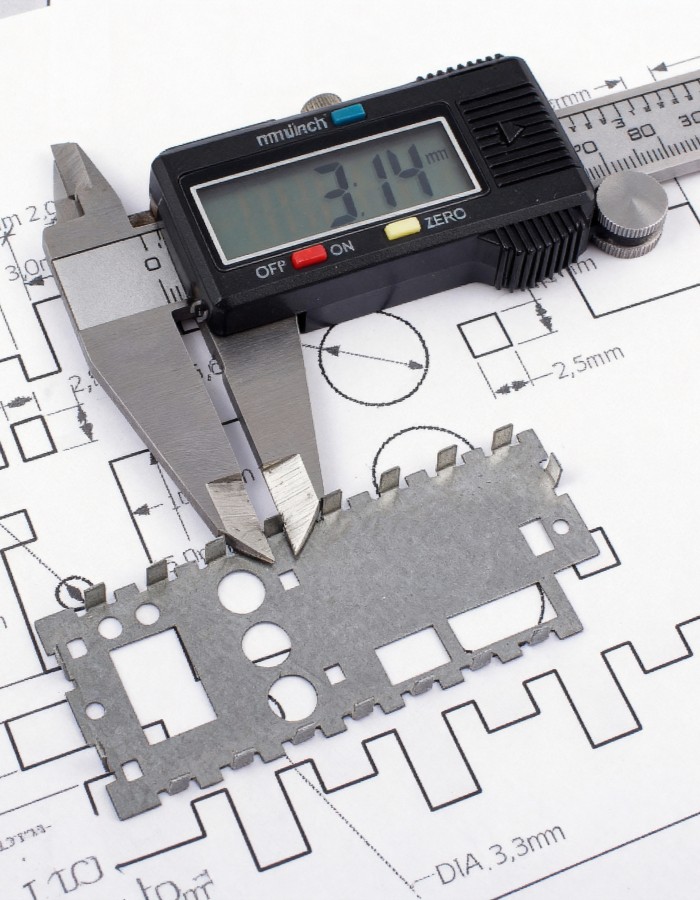

Sheet metal bending services are all about shaping flat sheets of metal into helpful parts by bending them at the right angles. It’s a process that uses special machines, like press brakes, to bend metal without breaking or cracking it. This way, you can get your metal pieces to fit exactly how you want for your project.

At ShincoFab, we make this easy for you. We offer custom sheet metal bending services that handle many types of metal and thicknesses. Whether you need a simple bend or a complex shape, we’ve got the right equipment and skilled team to get the job done right. We focus on precision, so your parts will match your designs closely. Plus, we work fast and at fair prices because we know how important keeping your project on schedule is.

When you choose ShincoFab, you get a partner who listens and supports your needs. Want to know what we can do for you? Reach out today! We’re here to help with your sheet metal bending needs and to provide a free quote. Let’s shape your next project together.

Our Sheet Metal Bending Capabilities

ShincoFab delivers comprehensive sheet metal bending services, handling various materials, thicknesses, and sizes with advanced equipment and skilled technicians to ensure precise, efficient, and scalable results

01.

Materials We Support

We work with a wide range of metals to meet diverse application requirements:

- Carbon steel

- Stainless steel

- Aluminum

- Galvanized steel

- Copper

- Brass

If you have a unique material request, our engineering team can evaluate and confirm feasibility.

02.

Thickness & Length Capacity

Our CNC press brakes can handle a variety of sheet dimensions:

- Max bending thickness: up to 12 mm / 0.47 inch (customizable per your actual spec)

- Max bending length: up to 3000 mm / 118 inch

- Minimum bend radius: aligned with material type and thickness (typically 1× material thickness for mild steel)

- Multi-step and complex bend sequences supported

03.

Equipment & Technology

To ensure stable quality and tight tolerances, we use modern bending equipment, including:

- CNC hydraulic press brakes

- Automated tooling systems

- Digital angle measurement

- High-tonnage bending capability for thicker materials

Our machines maintain excellent repeatability on both small and large batches.

04.

Bend Accuracy & Tolerances

We deliver precise, consistent results:

- Bend angle tolerance: typically ±1°

- Dimensional tolerance: down to ±0.2 mm (depending on geometry and material)

- Springback compensation calculated for every bend

- DFM analysis available for improved accuracy and manufacturability

05.

Flexible Production Volumes

We support all project sizes:

- Prototype bending (1–10 pcs)

- Small batches

- Mass production with stable repeatability

- Scheduled production available upon request

This flexibility helps you scale your product seamlessly from testing to full production.

06.

Design Files & Engineering Support

To streamline your workflow, we accept common file formats:

- DWG, DXF, PDF, STEP, IGES, and more

- Free design review to ensure manufacturability

- Suggestions for optimizing bend radius, flange length, hole positions, and cost-saving options

Why Choose Our Sheet Metal Bending Services

At ShincoFab, we make bending simple, precise, and fast. If you want parts that fit right and arrive on time, we’re ready to help. Reach out now to get a quote or talk with an engineer.

01.

Precision You Can Trust

We build parts that fit the first time. Our CNC press brakes, smart tooling, and digital angle checks help us hit tight tolerances on bend angles and dimensions. We plan for bend allowance, bend deduction, and springback, so your flat pattern turns into a part that matches your CAD. ShincoFab uses proven programs and calibrated tools to keep bends consistent across prototypes and production runs.

We also run first article inspections, in‑process checks, and final audits when you need them. Need PPAP or FAIR? We can do that. You get clear data and stable results you can count on. If you need close‑tolerance enclosures, brackets, channels, or hems, our sheet metal bending Services deliver. Ask ShincoFab for a sample or a quick DFM review today.

02.

Fast Turnaround, Flexible Volumes

Deadlines matter. We plan our jobs for quick cycle times and reliable ship dates. ShincoFab can turn prototype parts fast and scale to batch production without losing accuracy. We run multi‑step bends, complex geometries, and nested jobs with efficient setups, so you don’t wait. Short lead times are standard. Rush options are available when you need them.

No job is too small or too big. Order one piece to test a fit, then ramp to hundreds or thousands as your build grows. Our sheet metal bending Services support JIT schedules and repeat orders, so your line stays moving. Message us with your target date, and we’ll build a plan around it.

03.

One‑Stop Fabrication, From Cut to Finish

Save time by keeping everything under one roof. ShincoFab handles laser cutting, turret punching, bending, welding, hardware insertion, and surface finishing like powder coating, anodizing, passivation, and galvanizing. You get parts formed, finished, and ready for assembly with fewer handoffs and less risk. We process aluminum, stainless steel, carbon steel, galvanized steel, copper, and brass across common gauges.

Our team aligns bend radius, grain direction, hardware locations, and finish specs early, so downstream steps go smooth. That means fewer scratches, cleaner edges, and parts that assemble fast. With our sheet metal bending services and end‑to‑end flow, you cut cost and lead time. Share your drawings, and ShincoFab will quote the full job in one go.

04.

Helpful Engineering and DFM Support

Good design makes great parts. We help you tune bend radius, flange length, hole‑to‑bend distance, and relief cuts to avoid cracking or distortion. ShincoFab reviews your CAD, checks K‑factor assumptions, and suggests simple changes that reduce tool wear and improve accuracy. We can provide flat pattern callouts and gauge tables to match your material and tooling.

If you’re unsure about grain direction, die width, or minimum bend limits, we’ll walk you through options in plain language. We can prototype fast, then lock your bend data for repeat runs. With our sheet metal bending services, you get friendly, practical guidance that saves time and money. Send us your files, and we’ll return a clear manufacturability report.

05.

Quality, Traceability, and Compliance

Quality isn’t a box we tick, it’s how we work. ShincoFab tracks material certs, tool settings, and inspection data from start to finish. We use calibrated equipment, digital angle gauges, and CMM checks when needed to verify bend accuracy and dimensions. Need PPAP, FAIR, or traceability for regulated projects? We can support it with documented steps and clean records.

We focus on stable processes. That means consistent springback control, clean hems and flanges, and repeatable results across batches. If your project needs ISO-style procedures or customer-specific inspection plans, we set them up. With our Sheet Metal Bending Services, you get proof of quality, not just promises. Ask ShincoFab for sample reports or to set up a trial run.

06.

Clear Pricing and Real Communication

No guesswork. ShincoFab provides simple, transparent quotes with line-item detail for cutting, bending, hardware, and finishing. You’ll know lead times, tolerances, and packaging from the start. We give status updates, photos on request, and fast replies to changes. You get a single point of contact who understands your build and keeps things moving.

If you’re comparing options, we’ll show you cost-saving ideas without cutting corners. Fewer bends, smarter tooling, or adjusted flange lengths can lower costs. Our Sheet Metal Bending Services are built around your needs and your budget. Email or call ShincoFab anytime—we’ll answer quickly and get you what you need.

Precision Sheet Metal Bending Solutions Built for Your Next Project

Have a design challenge or custom requirement? Reach out now and get expert guidance—your next step to clearer answers and faster results.

Frequently Asked Questions

Welcome to our FAQ section! Here, you’ll find answers to the most common questions about our sheet metal bending service. If you want to learn more or have a unique requirement, don’t hesitate to get in touch with us.

1. What is sheet metal bending, and how does it work?

Sheet metal bending is a process where flat metal sheets are shaped by applying force to create angles or curves. We use special machines like press brakes that carefully press the metal to the desired shape without cutting or removing material.

Which metals can be bent using sheet metal bending services?

We can bend a wide range of metals, including carbon steel, stainless steel, aluminum, copper, brass, titanium, and more. The choice depends on your project needs and material thickness.

How thick of a metal sheet can you bend?

Our machines handle metal thicknesses from very thin sheets up to about 2 inches (50mm), depending on the material. Let us know your specs, and we’ll confirm feasibility.

What tolerances can I expect from sheet metal bending services?**

We typically achieve tight tolerances, often within ±0.2 mm for dimensions and ±1° for bend angles, so your parts fit perfectly. If you need higher precision, just ask!

Can you bend complex shapes or multiple bends in one part?**

Yes! We can create parts with multiple bends and complex profiles, thanks to our advanced CNC equipment and skilled operators. Share your design, and we’ll make it happen.

What is your cutting accuracy?

Our equipment delivers high precision with tolerances typically around ±0.1–0.2 mm depending on the metal and thickness. This level of accuracy is suitable for parts that need precise assembly or tight mechanical fit.

How do I prepare my design files for sheet metal bending?

It helps to provide clear CAD files in formats like DWG, DXF, or PDF with dimensions, bend lines, and angles marked. If you need help with design or file setup, we can guide you through the process.

What is springback, and how do you handle it?

Springback is a natural metal tendency to partially return to its original shape after bending. We compensate by adjusting the bending angle to ensure the final shape matches your design.

How long does sheet metal bending take?

Turnaround depends on order size and complexity, but many jobs ship within 1 to 2 weeks. Prototypes or small batches may be faster. Contact us for your project’s specific timeline.

How do you calculate pricing?

Our pricing considers several factors including material type and thickness, cutting time, complexity of the design, order quantity, and any required finishing services. If you send us your design file, we can provide an accurate quotation quickly.

Do you provide surface finishing or secondary services?

Absolutely! We offer finishing options like powder coating, anodizing, galvanizing, and painting, plus secondary processes like welding, laser cutting, and machining to deliver ready-to-use components.

What industries do you serve with your sheet metal bending services?

We work with many industries, including automotive, aerospace, construction, energy, marine, medical, and more. If your project requires high-quality bends, we’re here to help.

How do I get a quote or start a project?

Simply reach out with your drawings and requirements. We’ll review your needs, provide a competitive quote, and guide you through the next steps to get your sheet metal bending project underway.

Contact Us for Sheet Metal Bending Services

Have questions or ready to get started with your sheet metal bending service? We’re here to help! Whether you need a quick quote, technical advice, or want to discuss your project details, just reach out. Our team is ready to provide the support and expertise you need to make your custom metal bending easy and reliable. Let’s chat and find the best solution for your needs today!